Summary of Contents for HV2G

Page 1: ...H V 2 G R O TA R Y L A S E R I N S T R U C T I O N M A N U A L...

Page 5: ...5 Rotating laser port Charging port Control panel LASER OVERVIEW FRONT Battery screw...

Page 9: ...9 REMOTE CONTROL OVERVIEW BACK Battery compartment...

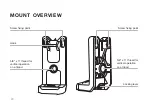

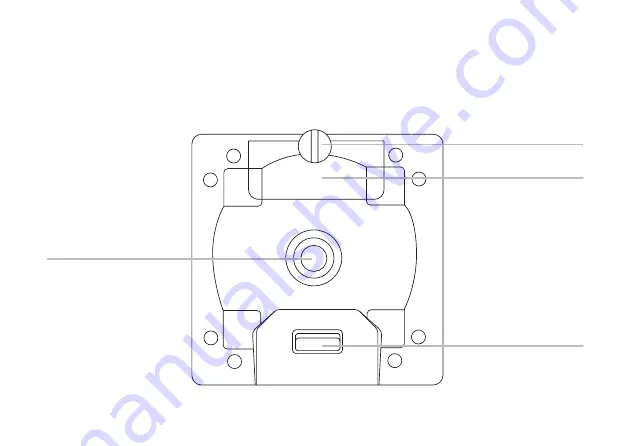

Page 11: ...11 DETECTOR OVERVIEW BACK Battery compartment Staff clamp thread LCD display screen...

Page 28: ...www spoton com au...