COD. 83119L.01EN

09//2016

17

5.3.3

- MEASURES TO BE TAKEN ON TO CROSS WALLS AND CEILINGS

To expel the gas duct outside, the flue duct has to cross some walls of the place where is installed, even

sometimes, it must pass through more than a stay up to the ridge.

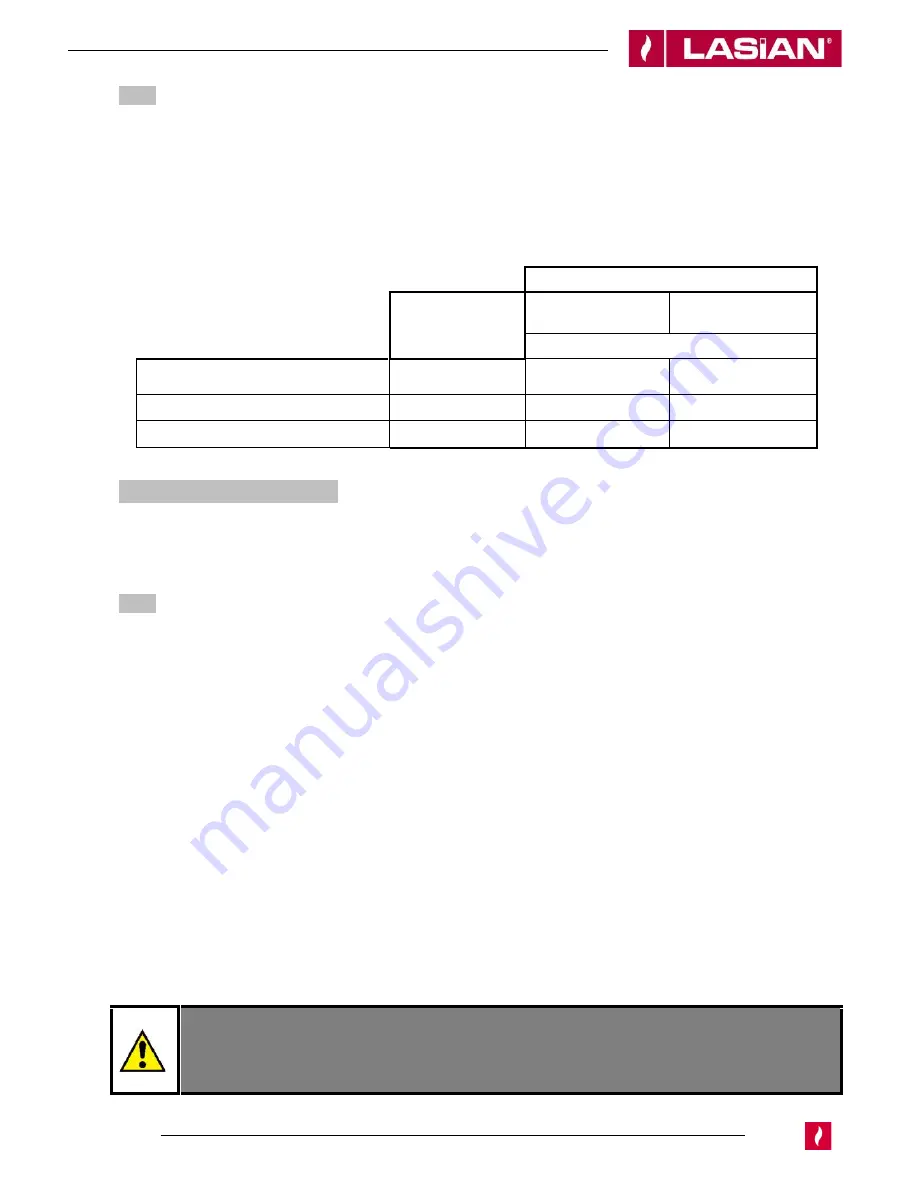

The size of the holes to practice depends on the duct diameter and the enclosure material to pass through. Once

the duct has been installed, the space between the hole and the duct must be with mineral-based insulating barrier

(rock wool, ceramic fiber), with a nominal density greater than 80 kg/m

3

.

Minimum holes to practice and insulation thickness table:

Diameter flue duct pipe [mm]

Insulation

thickness [mm]

Ø80

Up to 24 kW

Ø 100

From 28 kW

Diameter holes to be done [mm]

Wall in flammable wood or with

flammable parts

100

280

300

Wall or ceiling in cement

50

180

200

Wall or ceiling in brick

30

140

160

5.4 DUCT OR CHIMNEY

To expel outside the flue gas produced during the combustion in the stove, we need to connect it to a flue duct or

chimney.

5.4.1

- GENERAL NOTES

For the installation of the chimney, it must be taken into account the following points:

Each stove must have its own duct or chimney, in which it cannot been connected any other fireplace, stove, boiler

or any kind of extractor (

fig. 5.3

).

The chimney route will be as short as possible and it always will search the maximum vertical direction. The

diameter will be chosen according to the guidelines of paragraph

“5.4.2- CHOICE AND CALCULATION OF THE

DUCT”.

The inner section should be uniform, preferably circular: square or rectangular sections must have rounded edges

with a radius of at least 20 mm; regular bends without discontinuities, deviations from the axis no greater than 45°

(Fig. 5.4).

It is forbidden the installation of dampers or valves that could block the passage of flue gas.

Avoiding horizontal sections of chimney because this leads to fouling problems and it requires the cleaning of

these sections more frequently. In case of being unavoidable, it will give a minimal upward inclination in the

direction of gas flow, and a "T" will be installed in the changes of direction to clean the ducts without disassembly it

(

see Fig. 5.5

).

To install the duct certain distances and safety regulations must be observed (see paragraph “

5.3- DOMESTIC

FIRE PREVENTION

”).

The flue duct must always finish its route upright, and shall have on top a device called cowl (see paragraph

“

5.4.5- FLUE DUCT ENDING

”).

Always carry out the unloading installation so that periodic cleaning is assured without having to dismantle any

part. It is advisable that the flue is equipped with a solid material collection chamber and possible condensations

beneath the mouth of the duct to be easily opened and inspected from the door hermetically (

see Fig. 5.5

).

The draw of the smoke is forced thanks to an extractor that keeps the combustion chamber in

depression and all the discharge pipes under a slight pressure. It is required to verify that this

extractor is installed correctly and completely tight and firm, both for performance and safety.