COD. 79101EN.00

11/2013

12

3. FUEL

The multi-fuel boiler is designed to burn fuels derived from solid biomass:

Wood pellet: is a fuel made from compacted sawdust extracted from the remains of the production and processing

of dried natural wood; the compactness of the product is guaranteed over time by a natural substance contained in

the wood: the lignin. The typical form resembling small cylinders is achieved by wire drawing.

On the market there are various types of pellet with quality and features that change depending on the kind of

production and type of wood materials used.

Solid biomass

:

biomass is a type of fuel recovered and produced directly or indirectly from the disposal of

industrial processing, from substances such as olive, almond, hazelnut, rape or pruning cuts, or from the disposal

during wood processing or the remains. These fuels are materials such as shredded vegetables including olive pits,

almonds or hazelnut shells; other types are the pellet boiler and pellet olive of a diameter of 6 or 8 mm. etc. This

LASIAN boiler has an ash cleaning system that allows these fuels to be used in the devices, choosing the specific

program that is already recorded for the fuel we use:

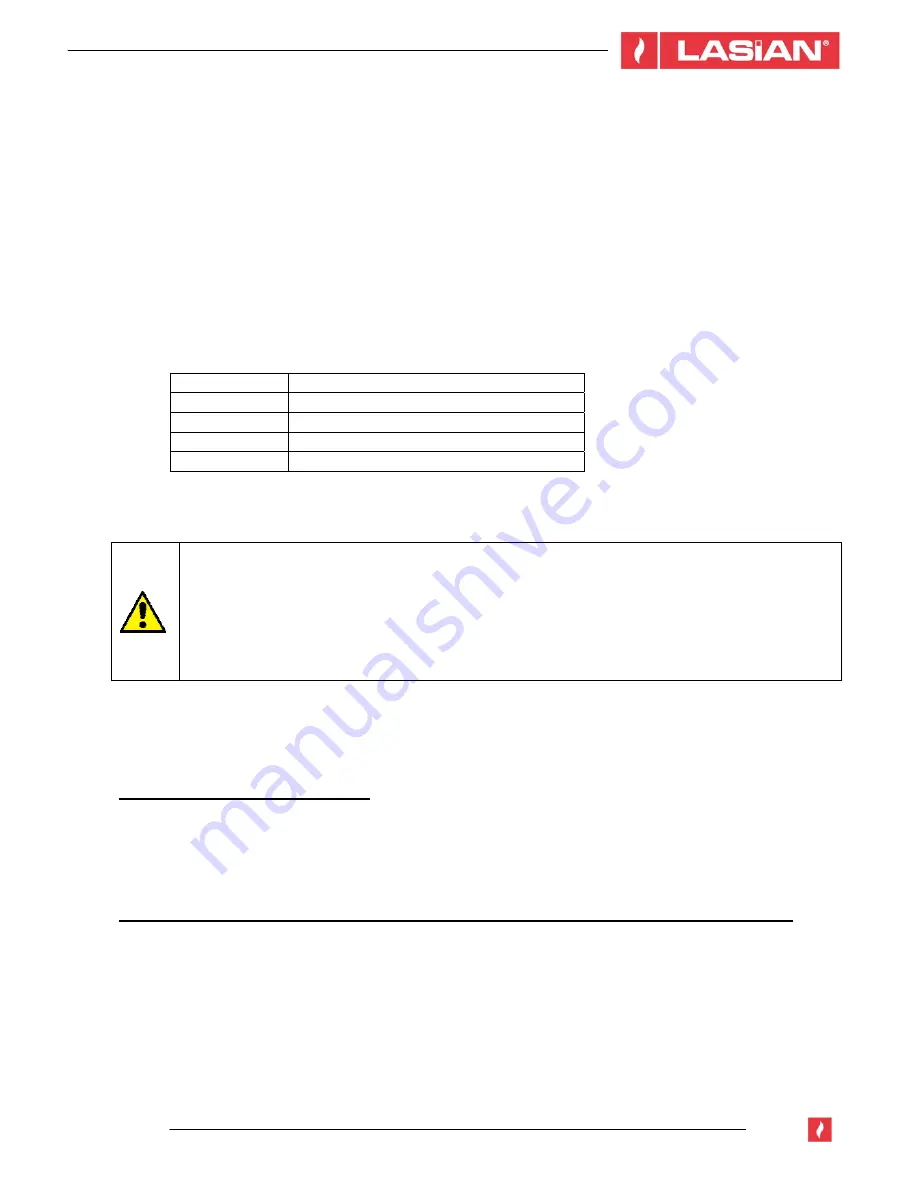

FUEL PROGRAMS:

Combustible 1

DIN PLUS

Combustible 2

PELLET QUALITY MEDIUM

Combustible 3

PELLET QUALITY LOW

Combustible 4

OLIVE PITS

Combustible 5

SHREDDED ALMOND SHELL

The importation of these programs can be found in chapter 8 Operation of the control panel, in the

paragraph 8.6.

ATTENTION!

The boiler is provided with two burners, one for the pellets and shredded almond shell

combustion (which is factory assembled) and another specific burner for olive pits combustion.

When you select the program “Combustible 4” for burning olive pits, the pellet burner must be

replaced by the olive pits burner, which has smaller holes.

The following types of fuel are excluded for its use; splinters - wood chunks - branches in

general.

Because the characteristics and fuel quality influence significantly in the autonomy, performance and

proper operation of the boiler, it is advised to:

AVOID the use of fuel containing powder of mixed sawdust, resins or chemical, additional or binder substances.

AVOID the use of wet fuel.

The choice of unsuitable fuel causes:

-

brazier and smoke exhaust dust jam,

-

increase in fuel consumption,

-

decrease in performance,

-

does not guarantee the normal operation of the boiler,

-

glass dirt,

-

production of unburned granules.

The presence of moisture in the fuel increases the volume of the capsules and breaks them causing:

-

malfunctions of the load system,

-

bad combustion.

Fuel must be stored in a dry place and special attention must be paid to the handling of the sacks in order to avoid

grinding them and form sawdust.

In order to use a fuel with size and calorific characteristics calorific different to the ones specified, it could be

necessary to modify the operating parameters of the boiler. Should that be your case, contact an authorized service

center.

Summary of Contents for BIOSELF

Page 1: ...COD 79101EN 00 11 2013 BIOSELF MULTIFUEL BOILER USER AND INSTALLATION MANUAL...

Page 2: ...COD 79101EN 00 11 2013 2...

Page 4: ...COD 79101EN 00 11 2013 4...

Page 38: ...COD 79101EN 00 11 2013 38...

Page 40: ...COD 79101EN 00 11 2013 40...

Page 41: ...COD 79101EN 00 11 2013 DATE WORKING HOURS INTERVENTION TAS SIGNATURE USER SIGNATURE...

Page 42: ...COD 79101EN 00 11 2013 42 DATE WORKING HOURS INTERVENTION TAS SIGNATURE USER SIGNATURE...

Page 43: ...COD 79101EN 00 11 2013 43 DATE WORKING HOURS INTERVENTION TAS SIGNATURE USER SIGNATURE...