COD. 79101EN.00

11/2013

13

The use of fuel not according to the manufacturer's instructions can damage the boiler and

compromise its performance, resulting in the invalidation of the warranty and in the end of the

liability of the manufacturer on the product.

4. INSTALLATION

4.1 GENERAL NOTES

Do not install the boiler in bedrooms, locations with bath or shower and in places where there is another heating

unit devoid of an adequate airflow (chimney, stove, etc.), outside exposed to the atmospheric agents or in wet

areas.

The installation of the boiler must be in a location that allows a safe and easy use and a simple maintenance. This

place must also be equipped with an electrical outlet with a regulatory earth connection.

The external air intake must meet the requirements of paragraphs 4.10 and 4.11.

ATTENTION!

Ensure that the plug for the electrical connection is accessible after the boiler

installation.

4.2 UNPACKING

Unpack the product carefully so it does not get damaged or scratched. Remove from the tank of the boiler, the

accessory and home box possible pieces of polystyrene or cardboard used to block the removable parts, etc.

Also keep out of reach of children parts of the packaging (plastic bags, polystyrene, etc.) that could be potentially

dangerous and dispose according to the existing laws.

4.3 DOMESTIC FIRE PREVENTION

- The installation and use of the boiler must comply with the manufacturer's instructions and local siting

regulations.

- Always consult the instructions given in this manual for a correct use of the boiler and the electronic devices

connected to it.

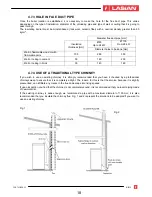

- When a chimney crosses a wall or ceiling it is necessary to perform particular operations (protection, thermal

insulation, distance of heat sensitive materials, etc.)

-

The chimney connection pipe should never cross a combustible surface.

-

Do not connect this boiler to another smoke duct already used by another device.

-

It is recommended to keep out of the heat source area and at least at one meter all flammable or combustible

items such as wooden beams, furniture, curtains, flammable liquids, etc...

-

In the event that there are flammable or heat sensitive coatings in the surrounding space, a protective layer of

insulating and not combustible material must be placed. If the floor is made of combustible material, fireproof

material protections projected 15 cm laterally and 30 cm from the front must be placed.

-

For further information refer to local regulations.

-

If the flue should catch fire, be equiped with a suitable systems for suffocating the flames or request help from

the fire service.

Summary of Contents for BIOSELF

Page 1: ...COD 79101EN 00 11 2013 BIOSELF MULTIFUEL BOILER USER AND INSTALLATION MANUAL...

Page 2: ...COD 79101EN 00 11 2013 2...

Page 4: ...COD 79101EN 00 11 2013 4...

Page 38: ...COD 79101EN 00 11 2013 38...

Page 40: ...COD 79101EN 00 11 2013 40...

Page 41: ...COD 79101EN 00 11 2013 DATE WORKING HOURS INTERVENTION TAS SIGNATURE USER SIGNATURE...

Page 42: ...COD 79101EN 00 11 2013 42 DATE WORKING HOURS INTERVENTION TAS SIGNATURE USER SIGNATURE...

Page 43: ...COD 79101EN 00 11 2013 43 DATE WORKING HOURS INTERVENTION TAS SIGNATURE USER SIGNATURE...