COD. 79101EN.00

11/2013

18

4.7.3 HOLE IN FLUE DUCT PIPE

Once the boiler location is established, it is necessary to make the hole for the flue duct pipe. This varies

depending on the type of installation, diameter of the unloading pipe and type of wall or ceiling that it is going to

pass through.

The insulating barrier must be mineral-based (rock wool, ceramic fiber) with a nominal density greater than 80

kg/m

3

.

Diameter flue duct pipe [mm]

Ø80

Up to 24 kW

Ø 100

From 28 kW

Insulation

thickness [mm]

Diameter holes to be done [mm]

Wall in flammable wood or with

flammable parts

100 280 300

Wall or ceiling in cement

50

180

200

Wall or ceiling in brick

30

140

160

4.7.4 USE OF A TRADITIONAL TYPE CHIMNEY

If you wish to use an existing chimney it is strongly recommended that you have it checked by a professional

chimneysweep to ensure that it is completely airtight. The reason for this is that the smoke, because it is slightly

pressurized, can infiltrate any cracks in the flue and escape into living spaces.

If upon inspection you find that the chimney is not completely sound, it is recommended that you insert piping made

of new material.

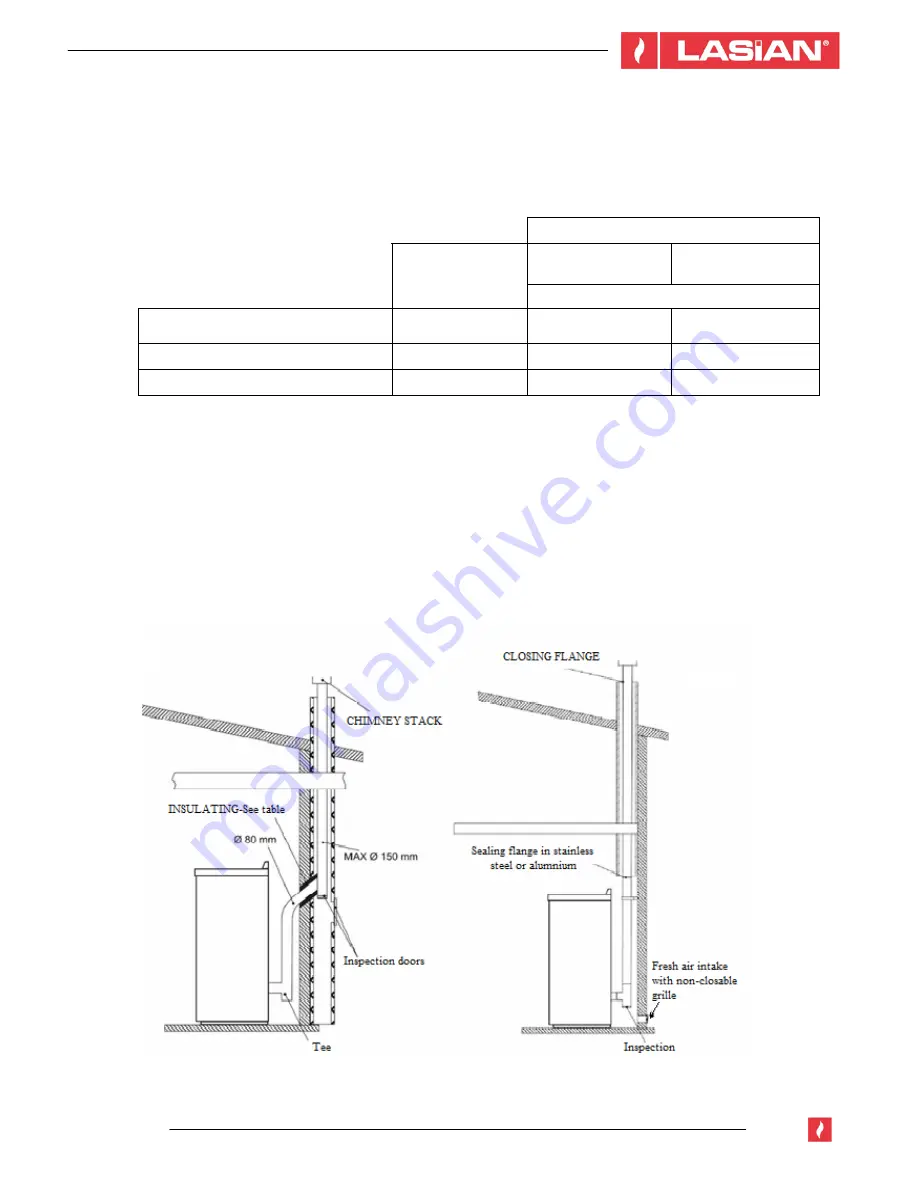

If the existing chimney is wide enough, we recommend a pipe with a maximum diameter of 150 mm; it is also

recommended that you insulate the chimney flue. Fig. 1 and 2 represent the solutions to be adopted if you want to

use an existing chimney.

Fig. 1

Fig. 2

Summary of Contents for BIOSELF

Page 1: ...COD 79101EN 00 11 2013 BIOSELF MULTIFUEL BOILER USER AND INSTALLATION MANUAL...

Page 2: ...COD 79101EN 00 11 2013 2...

Page 4: ...COD 79101EN 00 11 2013 4...

Page 38: ...COD 79101EN 00 11 2013 38...

Page 40: ...COD 79101EN 00 11 2013 40...

Page 41: ...COD 79101EN 00 11 2013 DATE WORKING HOURS INTERVENTION TAS SIGNATURE USER SIGNATURE...

Page 42: ...COD 79101EN 00 11 2013 42 DATE WORKING HOURS INTERVENTION TAS SIGNATURE USER SIGNATURE...

Page 43: ...COD 79101EN 00 11 2013 43 DATE WORKING HOURS INTERVENTION TAS SIGNATURE USER SIGNATURE...