4 - Operation

Page 09

4.3 - Leveling the Drill Bits

4.3.1

4.3.2

4.3.3

4.3.4

4.3.5

4.3.6

4.3.7

4.3.8

4.3.9

4.3.10

4.3.11

4.3.12

We recommend using a piece of card stock on the

Table when leveling the drill bits to avoid drilling into

the drill strip. This will lengthen the life of your drill bits

and keep them sharper.

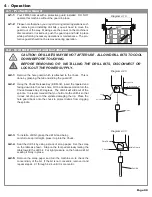

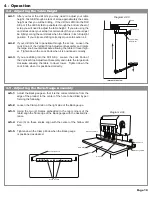

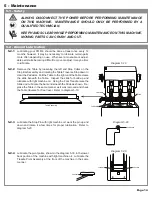

Remove one (1) of the two (2) Access Guard Screws

using the 1/8” Hex Wrench (HEX-18). Swing the Ac-

cess Guard as shown in diagram 4-40 to gain access

to the motor shaft.

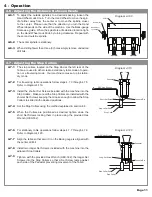

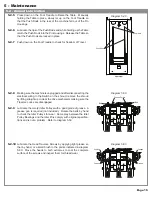

Insert the Spindle Rotation Tool (FMM9-957A) into the

end of the motor shaft through the opening in the top

of the machine shroud until the notch in the Spindle

Rotation Tool fits into the keyway securely.

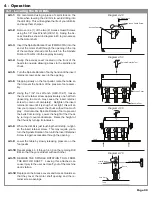

Swing the access cover located on the front of the

heads to one side allowing access to the spindle and

chuck.

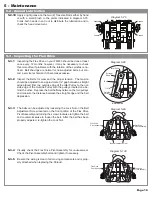

Turn the Spindle Rotation Tool by hand until the insert

retainer screw can be seen in the opening.

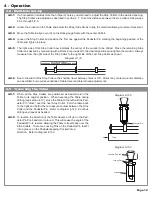

Stepping slowly on the foot pedal, raise the table so

that it meets the bottom of the pressure foot assem-

bly.

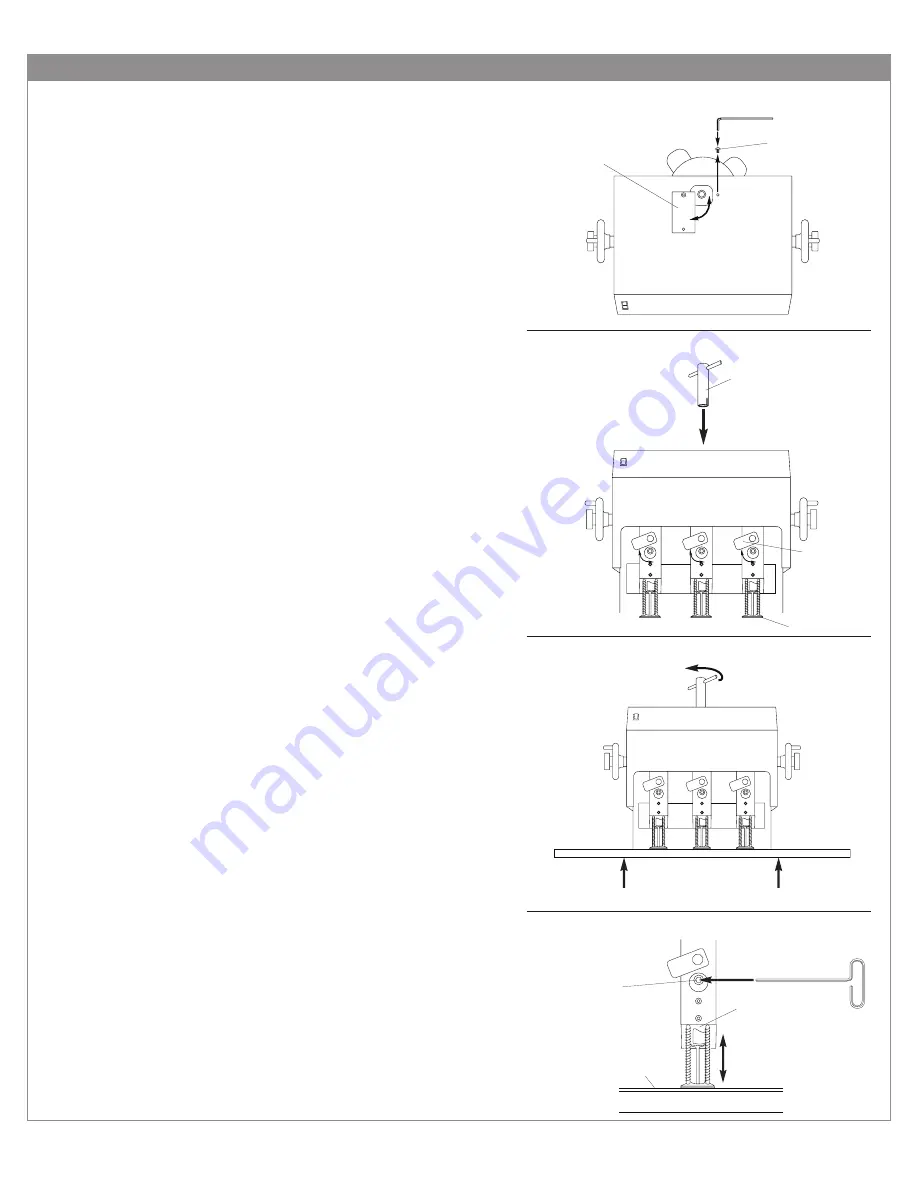

Using the 7/32” Hex Wrench (HEX-732-T), loosen

the insert retainer screw approximately one half turn

(loosening too much may cause the insert retainer

screw to come out completely). Retighten the insert

retainer screw until it is snug but not tight; this will al-

low you to raise or lower the chuck without too much

play. Hold onto the Spindle Rotation Tool to prevent

the belts from turning. Lower the height of the Chuck

by turning it counter-clockwise. Raise the height of

the Chuck by turning it clockwise.

When the drill bit is just touching the drill strip, re-tight-

en the insert retainer screw. This may require you to

turn the Spindle Rotation Tool until the Insert Retainer

Screw is again accessable through the opening.

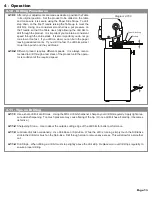

Lower the table by slowly releasing pressure on the

foot pedal.

Repeat steps 4.3.4 through 4.3.9 on the remaing Drill

Bits so that they are all level with each other.

REMOVE THE SPINDLE ROTATION TOOL FROM

THE MOTOR SHAFT. Leaving this attached can

cause injury to the user as it can fly out of the machine

upon startup.

Replace all the Access covers and Access Guards so

that they cover the motor shaft opening and the re-

tainer screw openings.

Diagram 4-50

Diagram 4-40

Access Guard

1/8” Hex Wrench

Access Guard Screw

Table

Diagram 4-60

7/32 Hex Wrench

Insert Retainer

Screw

Chuck

Table

Card Stock

Diagram 4-70

Spindle Rotation Tool

Access Cover

Pressure Foot