Maintenance

Urethane Bushings

5

5-12

Lastec//021819

Maintenance

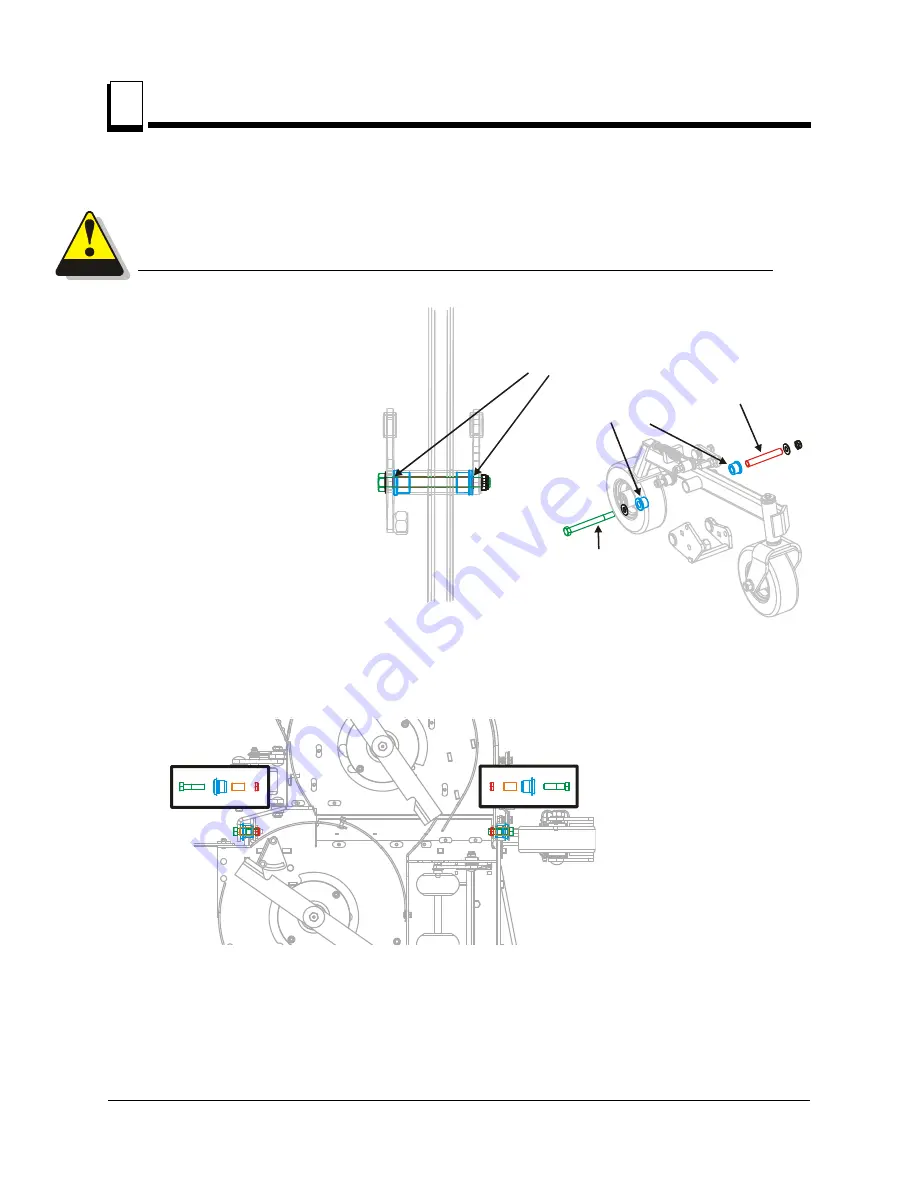

5.18 Urethane Bushings

CAUTION!

Bolts holding urethane bushings must remain tight.

Urethane bushings are

used throughout all Lastec

mowers in various applica-

tions, including (but not lim-

ited to) articulating deck

hinges and rocker arms. In

all cases, the bushings ride

on spacers that fit between

the rotating pieces of

framework, held tightly in

place with bolts.

It is

important that the spac-

ers remain tight between

the framework at all

times.

Failure to keep

these spacers tight will

result in premature wear on

the bolts, and equipment

damage.

Ensure that ALL bolts asso-

ciated with urethane bush-

ings are tight at all times.

In some cases, urethane

bushing applications are

associated with grease

points. The grease, in these

cases, is used to protect the

moving parts from corro-

sion due to water or other

contaminants, and is not

used for friction reduction.

Ensure grease fills the cav-

ity to prevent infiltration.

Caution

Spacer

Bushing

Spacer must be

drawn

to

framework by bolt

tight

Bolt

LT0090

LT0091B

Summary of Contents for 4500ZSR

Page 1: ...Lastec Mower 4500ZSR Owner s Manual Manual Part Man 4500ZSR ...

Page 6: ......

Page 7: ...Lastec 021819 1 1 1 SECTION 1 TO THE OWNER ...

Page 15: ...Lastec 021819 2 1 2 SECTION 2 SAFETY INFORMATION ...

Page 30: ......

Page 31: ...Lastec 021819 3 1 3 SECTION 3 INITIAL SET UP ...

Page 52: ......

Page 53: ...Lastec 021819 4 1 4 SECTION 4 OPERATING PROCEDURES ...

Page 64: ......