Initial Set-Up

Hydrostatic Pump Adjustment

Initial Set-Up

Lastec//020515

3-7

3

3.8

Hydrostatic Pump Adjustment

Danger

DANGER!

Always use jack stands when adjusting the hydrostatic pumps!

Keep everyone clear of all controls while adjusting the hydrostatic pumps!

Occasionally, you may need to adjust the

hydrostatic pumps to keep the drive wheels

from creeping. Follow these procedures to

adjust the pumps:

1.

Lift the rear of the drive unit until the drive

tires clear the ground. Use jack stands for

safety.

2.

Be sure steering control arms are locked in

neutral position.

3.

Start the drive unit, and set the throttle arm

to 3/4 full.

4.

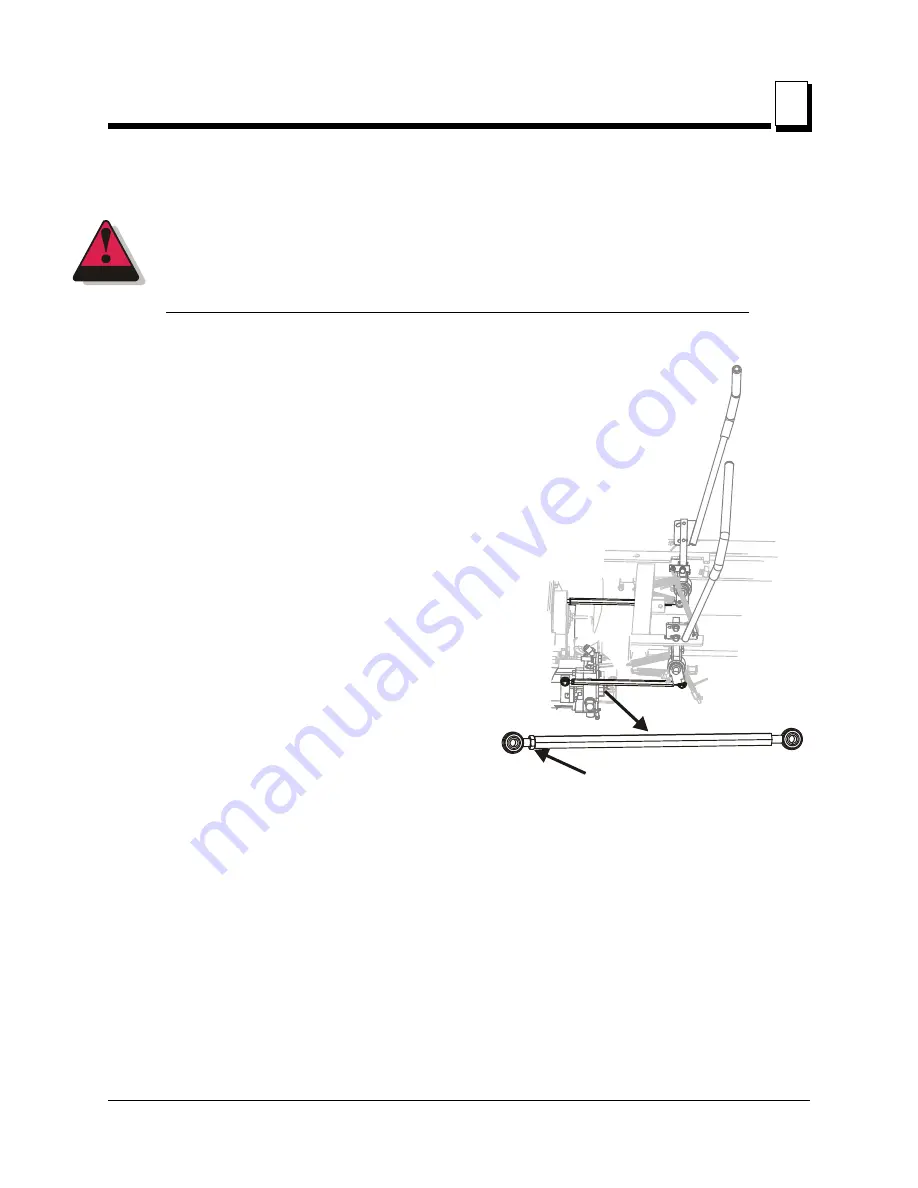

If either drive tire rotates, you need to adjust

the hydrostatic pump link arm for that tire.

(The link arm is attached to the bottom of the

steering control arm).

To adjust the link arm,

loosen the jam nut from the hydrostatic

pump link arm.

(The jam nut is located

between the rod end and the link arm).

Slowly turn the link arm, watching the tire as

it turns. If the tire begins turning faster, turn

the link arm in the opposite direction until it

slows, and eventually stops. Tighten the jam nut to lock the link arm into this position.

5.

When finished, turn off the drive unit.

6.

Be sure that both link arm jam nuts are tight.

7.

Lift the drive unit, remove the jack stands, and lower the unit to the ground.

Jam Nut

LT0108

Summary of Contents for Articulator 2661AGC

Page 6: ......

Page 7: ...Lastec 020515 1 1 1 SECTION 1 TO THE OWNER...

Page 15: ...Lastec 020515 2 1 2 SECTION 2 SAFETY INFORMATION...

Page 30: ......

Page 31: ...Lastec 020515 3 1 3 SECTION 3 INITIAL SET UP...

Page 49: ...Lastec 020515 4 1 4 SECTION 4 OPERATING PROCEDURES...

Page 57: ...Lastec 020515 5 1 5 SECTION 5 MAINTENANCE...

Page 68: ......