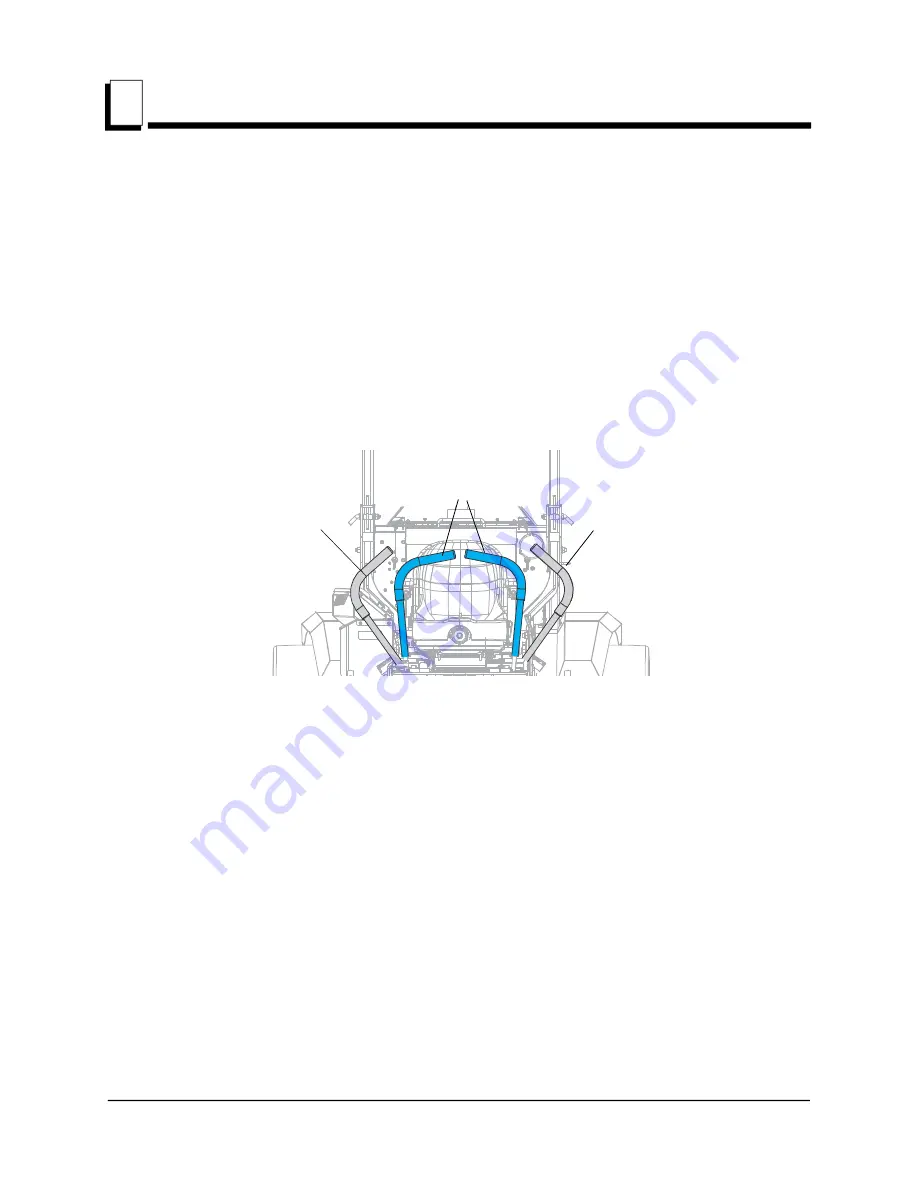

Operating Procedures

Steering levers

4-15

8/23/22

Operating Procedures

4

START MOTION

1.

Ensure that the machine is on flat, level ground.

2.

Start the engine in accordance with section 4.1 of this manual.

3.

Release the parking brake lever.

4.

Remove both steering control levers from the neutral lock position.

a.

Grasp each steering control lever with each hand.

b.

Pull them both toward the center of the unit until they are free from the neutral

lock.

Steering levers

NOTICE

In all cases, the further from neutral a steering lever is

pushed/pulled, the faster the travel for that drive wheel.

Avoid pivoting on one wheel. Turf damage may occur.

TDWZ1-23

Locked position

Locked position

Operating position