Maintenance

First 25 Operating Hours

5-2

8/18/20

Maintenance

5

Inspect the spindle bearing grease seals (under each deck) for grease leakage or

improper seating.

Lubricate all joints and moving parts which are not equipped with grease fittings.

Verify that all brake cables are functional, securely fastened and in good condition.

Verify proper installation, operation, and unobstructed flow of grass chute.

Inspect entire Lastec Mower for loose or entangled parts, debris, obstructions, mis-

placed tools, or any other possible safety hazards, equipment hazards or projectile

hazards. Clean off mowers of any dirt, grease, or oil.

Depending on current cutting conditions, brush out and clean the radiators and

hood grills periodically during the day to ensure proper flow of cooling air.

5.3

First 25 Operating Hours

Change the hydraulic oil and filter.

5.4

First 50 Operating Hours

Change engine oil and filter.

1

5.5

Every 50 Operating Hours

Inspect engine fuel lines and clamps. Replace as needed.

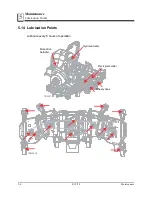

Grease all blade spindle bearing housings. Fill until grease purges from weep hole

in bearing housing.

Inspect all bushings for wear. Replace as needed.

Deck lift (2x front and 2x rear)

Deck wing actuator pivot (left and right)

Deck pivots (8 total)

Belt idler pivots (3 on deck, 1 on mule drive)

Check and clean if necessary any debris that may have accumulated during

operation.

1. Refer to the

Engine Operator’s Manual

accompanying this manual.