Maintenance

Torque Values

5

5-6

Lastec//042315

Maintenance

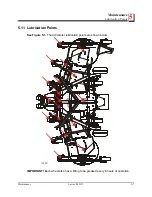

5.10 Torque Values

Below is a table of suggested torque values for this unit. Please use these torque values

on this unit unless otherwise specified.

Grade

Units

SAE 5

SAE 8

Tensile

Strength

105000

PSI

150000

PSI

Grade Mark

Bolt

Dia.

Threads.

Per In.

Units

SAE 5

SAE 8

6

8

10

10

12

1/4

1/4

5/16

5/16

3/8

3/8

7/16

7/16

1/2

1/2

9/16

9/16

5/8

5/8

3/4

3/4

7/8

7/8

1

32

32

24

32

24

20

28

18

24

16

24

14

20

13

20

12

18

11

18

10

16

9

14

8

in-lbs (Nm)

in-lbs (Nm)

in-lbs (Nm)

in-lbs (Nm)

in-lbs (Nm)

in-lbs (Nm)

in-lbs (Nm)

ft-lbs (Nm)

ft-lbs (Nm)

ft-lbs (Nm)

ft-lbs (Nm)

ft-lbs (Nm)

ft-lbs (Nm)

ft-lbs (Nm)

ft-lbs (Nm)

ft-lbs (Nm)

ft-lbs (Nm)

ft-lbs (Nm)

ft-lbs (Nm)

ft-lbs (Nm)

ft-lbs (Nm)

ft-lbs (Nm)

ft-lbs (Nm)

ft-lbs (Nm)

20 (2.3)

24 (2.7)

35 (4.0)

40 (4.5)

50 (5.7)

95 (10.7)

95 (10.7)

17 (22.6)

20 (27.1)

30 (40.7)

35 (47.5)

50 (67.8)

55 (74.6)

75 (101.7)

85 (115.3)

105 (142.4)

115 (155.9)

150 (203.4)

160 (217.0)

170 (230.5)

175 (237.3)

302 (409.5)

300 (406.8)

466 (631.8)

-

30 (3.4)

45 (5.1)

50 (5.7)

65 (7.3)

125 (14.1)

150 (17.0)

23 (31.2)

25 (33.8)

40 (54.2)

45 (61.0)

65 (88.1)

70 (94.9)

100 (135.6)

110 (149.2)

135 (183.1)

150 (203.4)

195 (264.4)

210 (284.8)

220 (298.3)

225 (305.1)

473 (640.9)

400 (542.4)

714 (967.4)

Summary of Contents for Man-120ER

Page 5: ...Lastec 042315 1 1 1 SECTION 1 TO THE OWNER...

Page 12: ......

Page 13: ...Safety Information Safety Information Lastec 042315 2 1 2 SECTION 2 SAFETY INFORMATION...

Page 25: ...Initial Set Up Initial Set Up Lastec 042315 3 1 3 SECTION 3 INITIAL SET UP...

Page 35: ...Lastec 042315 4 1 4 SECTION 4 OPERATING PROCEDURES...

Page 43: ...Maintenance Maintenance Lastec 042315 5 1 5 SECTION 5 MAINTENANCE...