Initial Setup

XR700T 2/28/22

3-8

Initial Setup

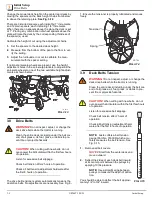

Pre-Operation Equipment Inspection Checklist

3

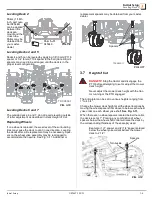

Verify that all warning decals are in place, visible and

legible.

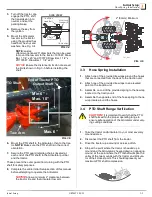

Verify that all covers, guards, and safety devices are

properly installed and secure.

Check that the discharge chute is clear of debris,

properly mounted, and in good condition.

Inspect entire Articulator for loose or entangled parts,

debris, obstructions, or neglected tools.

Perform all safety, set-up, and pre-operation proce-

dures listed in your tractor manual.

Complete the appropriate maintenance checklist (Sec-

tion 5).