Maintenance

Every 100 Operating Hours

5

5-2

WZ1000 6/5/23

Maintenance

5.6 Every 100 Operating Hours

Inspect air cleaner and filter elements. Replace as needed.

1

Inspect engine fan and alternator belt. Replace as needed.

5.7 Every 200 Operating Hours

Change engine oil and filter.

1

5.8 Every 400 Operating Hours

Replace fuel filter cartridge.

1

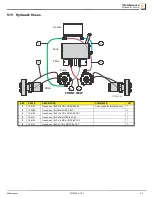

Change the hydraulic oil and filter.

5.9 Every 500 Hours

Inspect and re-pack all wheel bearings.

Flush fuel tanks.

1

Flush radiator.

1

Replace engine fan and alternator belts.

1

Check engine valve clearance

1

Check head mounting bolt torque (while doing valve check)

1

5.10 Annual

Inspect air cleaner filter elements and replace if necessary.

1

Change the hydraulic oil and filter.

Rotate tires.

5.11 Bi-Annual

Replace fuel lines and clamps.

1

Replace radiator hoses and clamps.

1

Replace battery.

5.12 Urethane Bushings

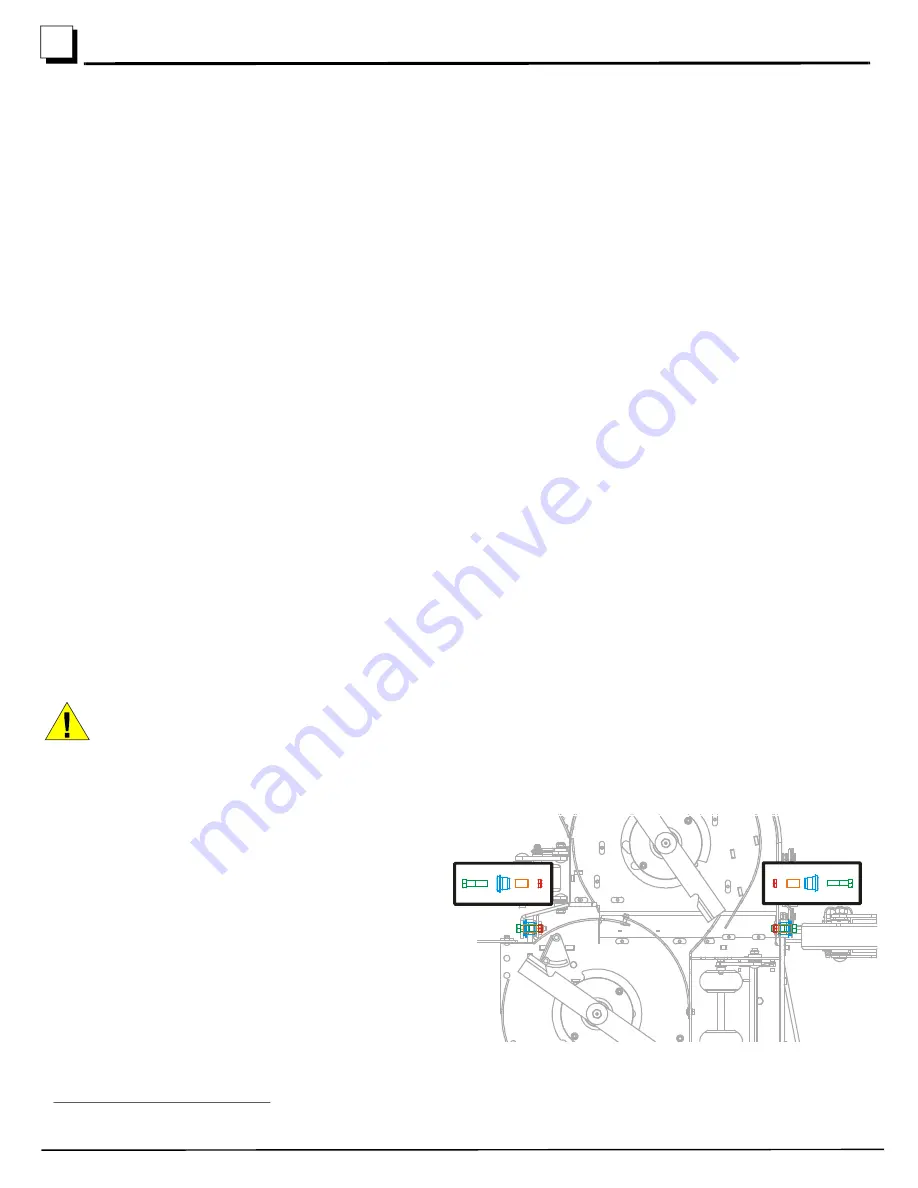

CAUTION!

Bolts holding urethane bushings must remain tight. Failure to keep these spacers tight will result in prema

-

ture wear on the bolts, and equipment damage.

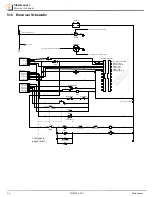

Urethane bushings ride on spacers that fit between the rotating pieces of framework, held tightly in place with bolts.

It is

important that the spacers remain tight between the framework at all times.

Ensure that ALL bolts associated with urethane bushings

are tight at all times.

Urethane bushing applications may be associated with

grease points.

The grease, in these cases, is used to protect the moving

parts from corrosion due to water or other contaminants, and

is not used for friction reduction.

Ensure grease fills the cavity to prevent infiltration.

1. Refer to the Engine Operator’s Manual accompanying this manual.

LT0091B