Maintenance

Hydraulic Hoses

5

Maintenance

WZ1000 6/5/23

5-5

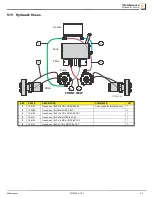

5.15 Hydraulic Hoses

REF

PART #

DESCRIPTION

COMMENTS

QTY

1

106133

Hose Assy, 1/2LPx20-1/2In ORFS 8 45-45

Color coded for illustration only

1

2

105986

Hose Assy, 1/2HPx32in ORFS 8 ST

4

3

106129

Hose Assy, 1/2LPx10-1/2In ORFS 8 ST-ST

1

4

106131

Hose Assy, 1/2LPx24In ORFS 8 ST-45

1

5

106135

Hose Assy, 1/2LPx14-3/8In ORFS 8 ST-45

1

6

106137

Hose Assy, 1/2LPx7-1/2In ORFS 8 ST-ST

1

TDWZ1-21

1

2

3

4

5

6

FRONT VIEW

Cooler

Filter

Tank

Pump

Motor