36 / 125

ECO Silver

10/2019 i

6.4

Heat transfer liquids, cooling water and hoses

Note:

–

Tap water may be unsuitable for operation due to the calcium carbonate content. The bath vessel may calcify.

–

High purity water (from ion exchangers) and distilled or bidistilled water are unsuitable for operation due to the

corrosive properties of these media. High purity water and distillates are suitable as a medium after the addition

of 0.1 g of soda (Na

2

CO

3

, sodium carbonate) per liter of water.

–

Water containing iron (rust formation), chlorine (pitting) and untreated river water ("algae formation") is unsuit-

able.

–

The bath vessels of the LAUDA ECO thermostats are produced in stainless steel 1.4301 and are accordingly

resistant to mechanical and chemical stresses.

–

Metals have different electrochemical potentials. Therefore, in the case of direct contact between the tank and a

frame (copper for example) electrochemical oxidation may occur. The bath corrodes despite the use of high

quality materials on the tank. Avoid the use of this type of frame or direct contact with it or contact with non-

ferrous metal samples and the inside of the container. Use original LAUDA stainless steel frames or commer-

cially available frames in temperature-resistant plastics.

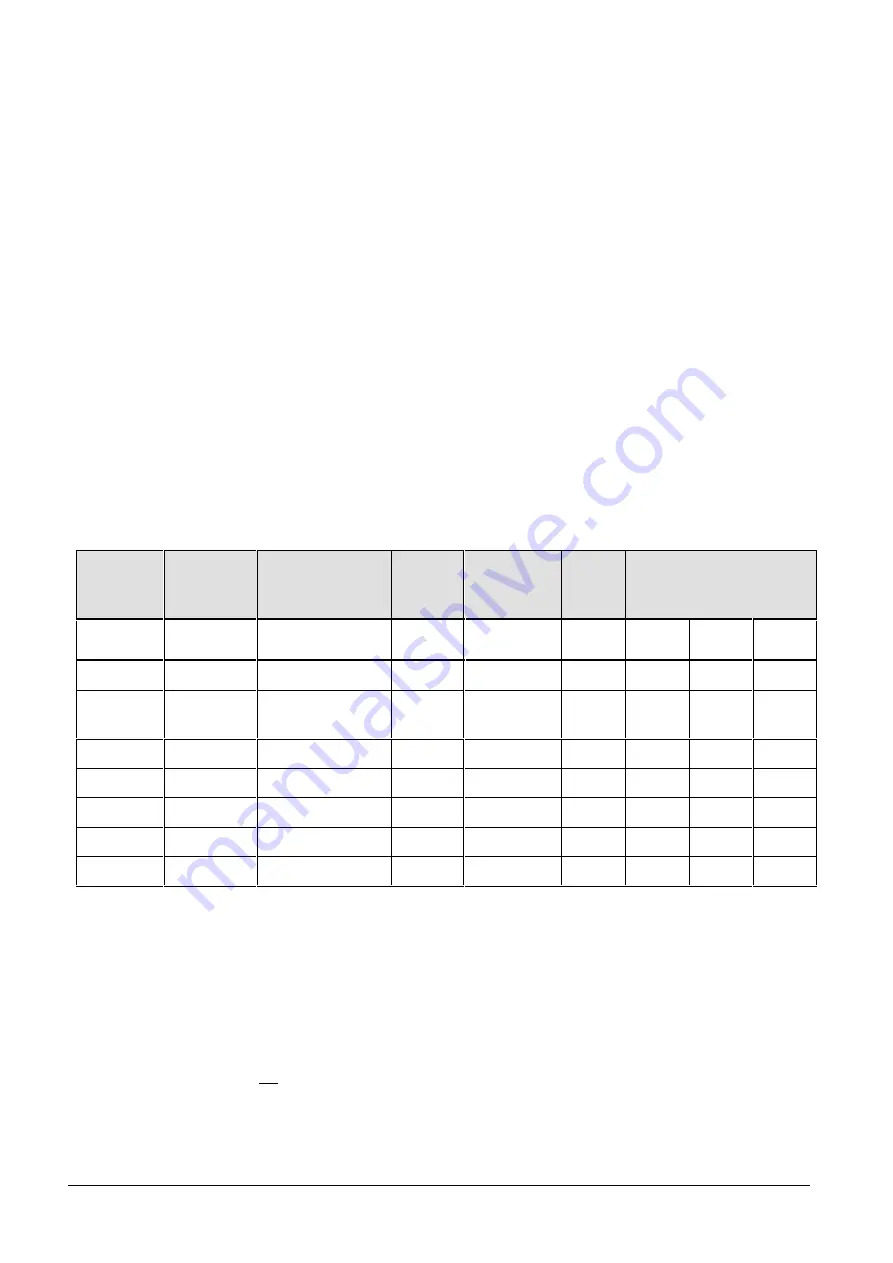

a) Approved heat transfer liquids

LAUDA

designation

Operating

temperature

range

Chemical

characterisation

Viscosity

(kin)

Viscosity

(kin)

at

temperature

Flash

point

Container size

Catalogue number

°C

mm²/s at

20 °C

mm²/s

°C

5 L

10 L

20 L

Kryo 51

-50 – 120

Silicone oil

5

34 at -50 °C

120

LZB 121 LZB 221 LZB 321

Kryo 30

-30 – 90

Monoethylene

glycol/water mixture

4

50 at -25 °C

119

LZB 109 LZB 209 LZB 309

Kryo 20

-20 – 170

Silicone oil

11

28 at -20 °C

170

LZB 116 LZB 216 LZB 316

Therm 160

60 – 160

Polyalkylene glycol

141

5 at 140 °C

260

LZB 106 LZB 206 LZB 306

Therm 180

0 – 180

Silicone oil

23

36 at 0 °C

250

LZB 114 LZB 214 LZB 314

Therm 250

50 – 250

Silicone oil

125

45 at 50 °C

300

LZB 122 LZB 222 LZB 322

Aqua 90

5 – 90

decalcified water

1

--

--

LZB 120 LZB 220 LZB 320

At higher temperatures vaporization losses occur. In this case use a bath cover (

9). Use distilled water or pure

demineralized water only after adding 0.1 g of soda (Na

2

CO

3

sodium carbonate) per liter of water. Otherwise

there is the risk of corrosion!

The proportion of water reduces with longer working at high temperatures and the mixture becomes flammable

(flash point 119 °C). Check the mixing ratio using a hydrometer.

Not suitable for polycarbonate baths.

–

Silicone hoses are not suitable for silicone oils!

–

EPDM hoses are not suitable for mineral oils.

Summary of Contents for ECO Silver E 10 S

Page 1: ...ECO Silver Operation manual ...

Page 2: ......

Page 4: ......

Page 78: ...78 124 ECO Silver 10 2019 i ...

Page 79: ...10 2019 i ECO Silver 79 124 ...

Page 80: ...80 124 ECO Silver 10 2019 i Appendix with settings ...

Page 111: ...10 2019 i ECO Silver 111 124 5 Click on Continue installation 6 Click on the key Finish ...

Page 113: ...10 2019 i ECO Silver 113 124 ...

Page 120: ...120 124 ECO Silver 10 2019 i Blank page ...

Page 121: ...10 2019 i ECO Silver 121 124 Blank page ...

Page 122: ...122 124 ECO Silver 10 2019 i ...

Page 125: ......

Page 126: ......

Page 127: ......