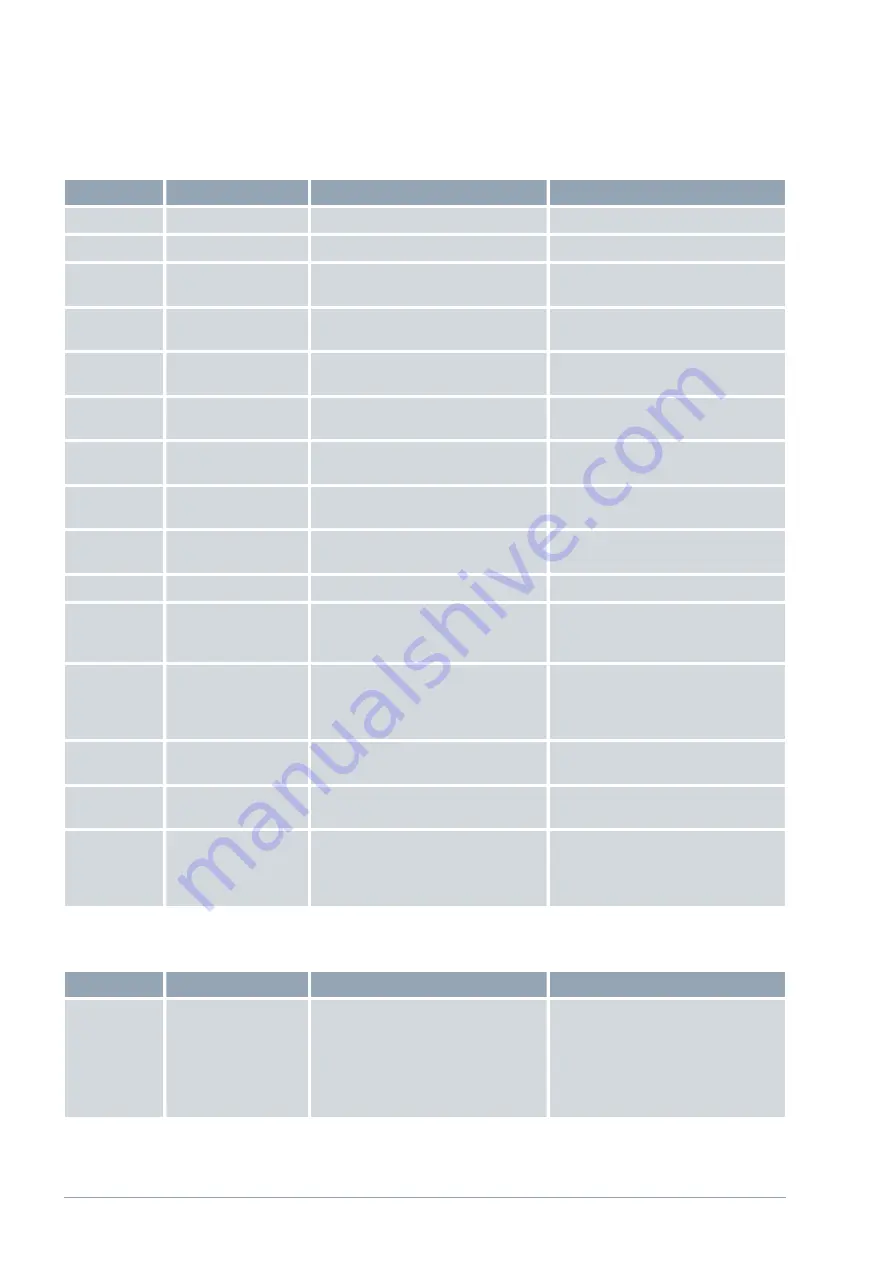

Code

Message

Description

User action

7

No water

No cooling water connected

Provide a supply of cooling water

8

---

---

---

9

T ext Pt100

No actual value from the Pt100

module

Check the temperature probe

10

T ext analog

No actual value from the analog inter-

face

Check the temperature probe

11

T ext serial

No actual value from the serial inter-

face

Check the serial connection

12

Analog input 1

Analog module: Current interface 1,

interruption.

Check the connection

13

Analog input 2

Analog module: Current interface 2,

interruption.

Check the connection

14

High level

Float detects high level

Drain excess heat transfer liquid from

the device. Caution: risk of burns

15

Digital input

Interference signal at the input of the

contact module

(customer application)

16

Refilling

Heat transfer liquid level is too low

Refilling the heat transfer liquid

19

Gage pressure

Gage pressure in the outflow

Reduce/eliminate the hydraulic resist-

ance in the hoses or/and in the con-

sumer

20

T ext Ethernet

No actual value from the Ethernet

interface

Check the serial connection

Check whether the control station

specifies the actual temperature via

the Ethernet interface

22

Communication inter-

rupted

Connection to the control station

interrupted

Check the cable connection

23

T ext EtherCAT

No actual value from the EtherCAT

interface

Check the serial connection

24

Overtemperature

Overtemperature in expansion vessel

(T > TmaxTank)

Overtemperature in devices with pres-

sure overlay (T > Tmax_Return)

Allow the device to cool down

Table 42: Flow Controller Alarms

Code

Message

Description

User action

55

Flow meter timeout

Error in the LiBus cable connection

n

Switch off the constant tem-

perature equipment

n

Check the LiBus cable connection

and restore if necessary

n

Switching the constant tem-

perature equipment on

V6

Integral Process Thermostats and High-Temperature Thermostats

148 / 198