Integral XT

YAWE0028 / 24/06/2016

Starting up

95

7.15.3.1

Procedure for setting the control parameters for internal control

1. Choose a set of control parameters from the table of control parameters (

þ

2. Adjust the setpoint by 5 °C (5 K setpoint step change) and record the outflow temperature for

at least 5 minutes.

3. If the outflow temperature oscillates (>0.1 K), then enlarge

Xp

until the oscillation dies

away. Always wait a number of minutes between the changes.

4. +20 K setpoint step change, await transient response,

-20 K setpoint step change, await transient response.

5. Assess transient responses:

- if an overshoot is to be reduced, then slowly increase Tv (until about 90 % of Tn),

- if settling is too slow, then reduce Tv to about 60 % of Tn,

- always adjust Td:

Td

= 20 % of Tv,

- after each change repeat Point 4. Carry out and evaluate ±20 K setpoint step changes.

6. If the response takes too long, then Tn can be reduced. Similarly reduce Tv, Td as a per-

centage. Reduce

Xp

to 70...50 % so that the system oscillates. Then continue from Point 2.

7. If the tendency to oscillate increases without the overshoot being acceptably reduced, then

a)

Xp

can be slightly increased; continue with Point 3,

b) larger time constants should be chosen: Increase

Tn

,

Tv

,

Td

by 30...80 %,

and

Xp

to 70...50 % so that the system oscillates. Then continue from Point 2.

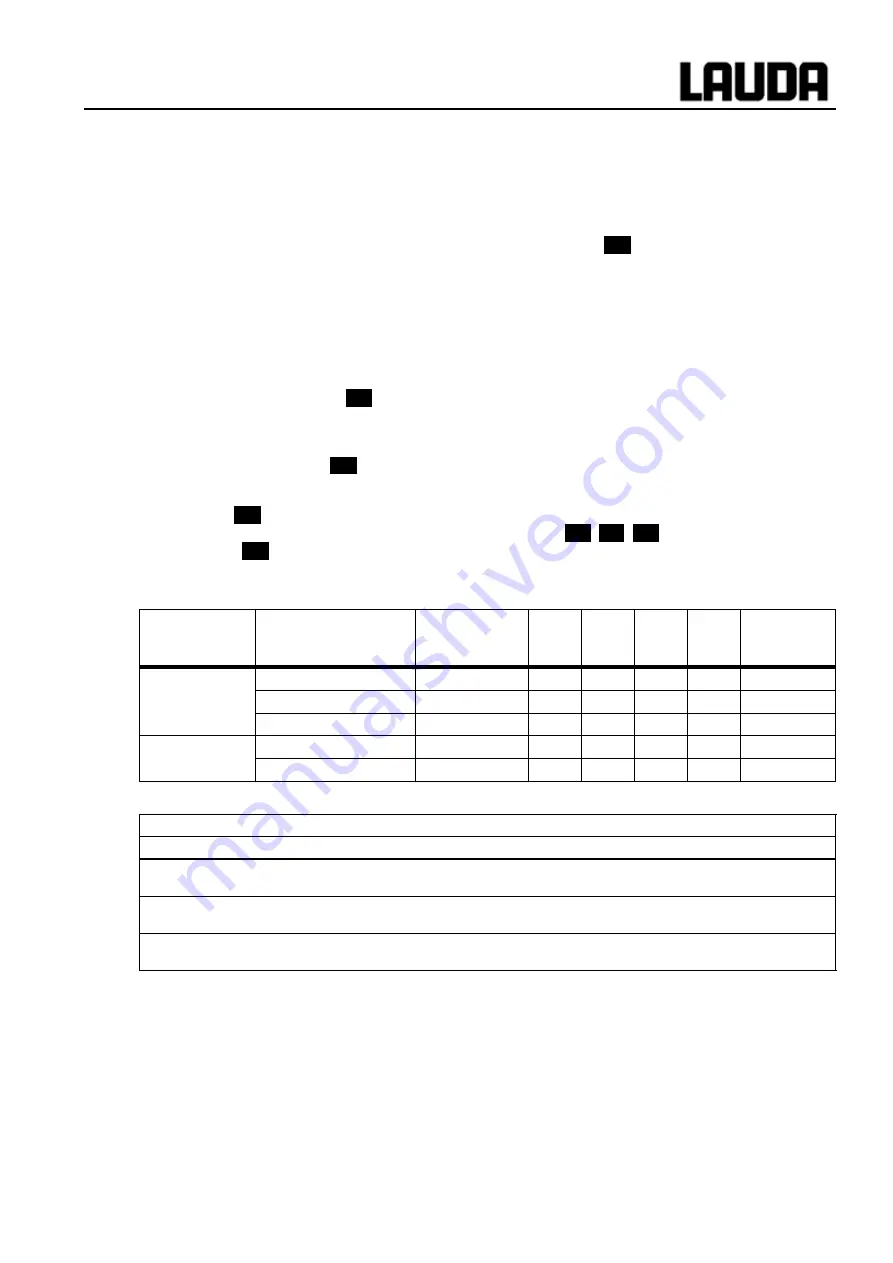

7.15.3.2

Table with control parameters and pump level for internal control

Outflow

control

Device type

Heat transfer liquid

in the outflow

External ap-

plication

Xp

_P

Tn

tn

Tv

tu

Td

td

Pump level

XT 150,

XT 250 W

KRYO 30

a)

30

80

68

15

6

KRYO 30

b)

40

100

84

18

4

KRYO 55

c)

30

50

40

8

3

XT 750 H,

XT 950 W

KRYO 55

d)

50

50

40

8

8

KRYO 55

e)

80

100

85

16

5

Description

a)

20 m pipe, D = 10 mm (internal), bypass used.

b)

20 m pipe, D = 10 mm (internal), bypass used.

c)

Glass double-shell reactor with 4 liters, uninsulated, thermostatic oil in the reactor, 2 x 1.5 m metal

corrugated hose D = 10 mm (internal).

d)

Metal double-shell reactor, 17 liters of thermostatic oil in the reactor, 2 x 1.5 m metal corrugated

hose D = 20 mm

e)

Glass double-shell reactor with 4 liters, uninsulated, thermostatic oil in the reactor, 2 x 5 m metal

corrugated hose D = 10 mm (internal), bypass used.

Summary of Contents for Integral XT 150

Page 2: ......

Page 4: ......

Page 164: ...Integral XT 162 YAWE0028 24 06 2016 Intentionally left blank ...

Page 166: ......

Page 167: ......