6.

Continuously top up or recirculate the descaler. Continue this process

until the foaming reaction had subsided. This usually takes 20 to

30 minutes.

7.

Then drain the condenser using compressed air.

“Draining the water-cooled condenser”

for detailed information on draining the con-

denser.

8.

Rinse the device thoroughly with fresh water.

Make sure a minimum of 10 liters of water flows through the

system.

9.

You can now connect the device back to the cooling water supply.

1.

Switch off the device at the mains switch.

2.

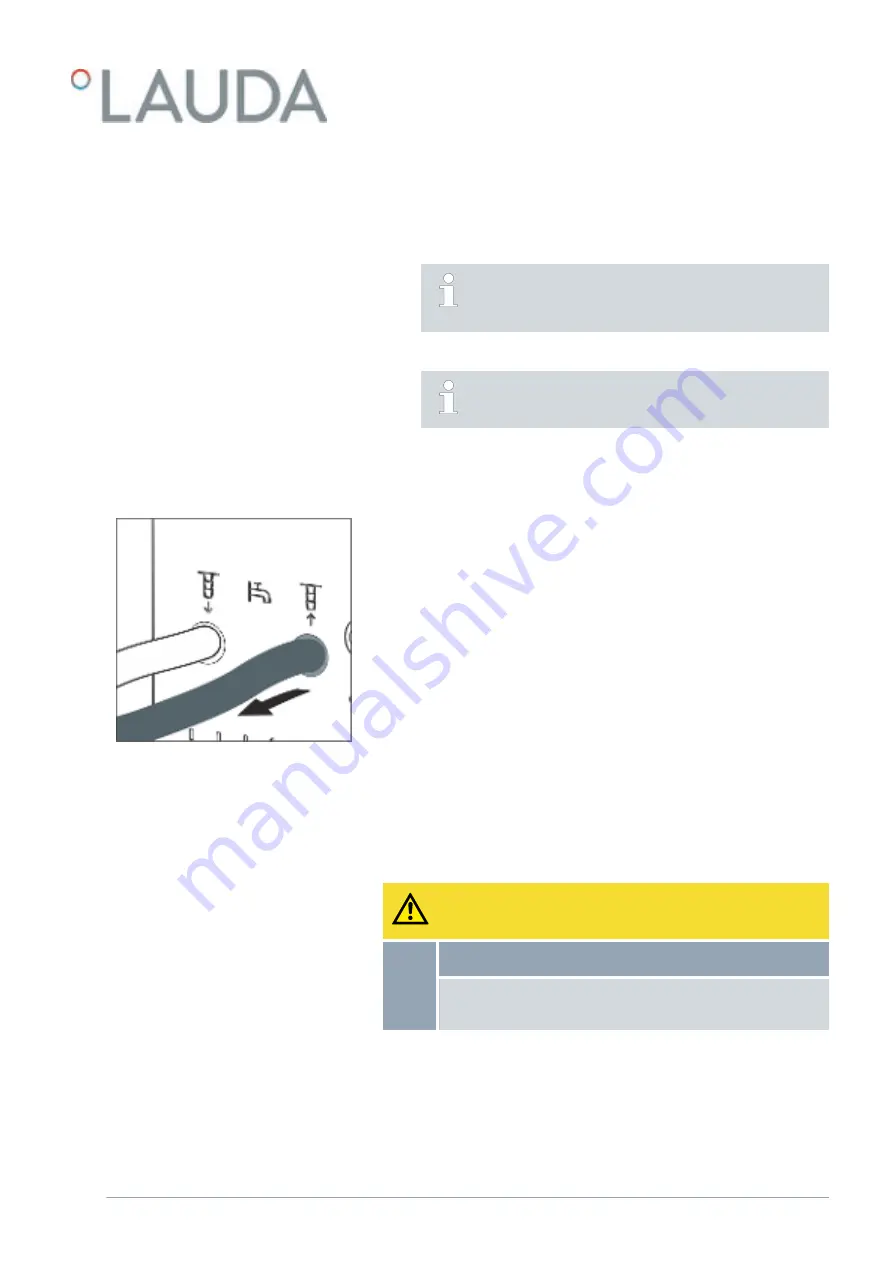

Detach the cooling water hose from the cooling water supply intake.

Leave the hose on the cooling water outlet (OUT) attached securely

to the device.

3.

Allow compressed air to flow through the cooling water hose towards

the device. Wait until all the water has flowed out of the device before

detaching the compressed air supply.

7.6 Checking the heat transfer liquid

Contaminated or degenerated heat transfer liquid must be replaced. Con-

tinued use of the heat transfer liquid is only permitted following successful

testing. The heat transfer liquid must be tested as outlined in DIN 51529.

CAUTION!

Contact with hot/cold heat transfer liquid

Scalding, cold burns

Bring the heat transfer liquid to room temperature for anal-

ysis.

7.7 Checking the overtemperature protection

The device must be switched off if the bath temperature exceeds the max-

imum temperature [Tmax]. The electronics system switches off the device

components.

Draining the water-cooled condenser

Fig. 75: Cooling water connection socket

V6

PRO bath thermostats and circulation thermostats

117 / 156

Summary of Contents for P 10

Page 146: ...V6 PRO bath thermostats and circulation thermostats 146 156 ...

Page 147: ...V6 PRO bath thermostats and circulation thermostats 147 156 ...

Page 148: ...V6 PRO bath thermostats and circulation thermostats 148 156 ...

Page 157: ......

Page 158: ......

Page 159: ......