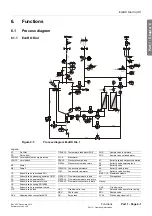

Functions

Part 1 • Page 6-7

Part 1 – Operating Instructions

Rev. 4.00 December 2014

Software version 1.04

EcoRO Dia I/II (HT)

Part 1 • Chapt

er 6

6.2.8

Loop pressure

The following factors determine the pressure ratios in a loop:

•

The maximum consumption (number of dialysis stations and other consumers)

•

The minimum flow speed required (to avoid contamination)

•

The minimum supply pressure at the last tapping point

•

The pipe geometry (pipe cross-section etc.)

The overflow valve

UV1

at the end of the loop must be set according to customer requirements. Without

permeate discharge and maximum performance, the setting pressure via

UV1

should be 2.0–3.5 bar.

The flow speed in the primary loop should reach 0.5 m/s (with full discharge).

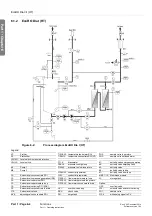

6.2.9

Membrane pressure vessel in the loop

The required constant pressure and an adequate supply of permeate is ensured by installing a membrane

pressure vessel. In turn, the size of the vessel and the necessary membrane air pressure depend on the

factors listed under

part 1, chapter 6.2.7 “System production pressure”.

LMW recommends a daily check of the Hydrowatch on the installed membrane pressure vessel (DG).

If the red indicator is visible in the viewing glass, please contact your Lauer Membran Wassertechnik

GmbH service technician immediately.

6.2.10 Prevention of excess pressure in the loop

An increase in pressure after reverse osmosis may well be possible if a butterfly valve is blocking the loop.

The pressure switch

PSAH1

prevents the pressure increasing above the set value. After the system is

switched off, the corresponding message appears on the display

part 1, chapter 14. A faulty expansion

membrane on the surge tank also leads to an increase in pressure when the system is switched on, and

thus to the system being switched off via pressure switch

PSAH1

(factory setting: switch-off pressure =

6 bar / switch-on pressure = 4 bar).

6.2.11 Temperature-dependent discharge

6.2.11.1 Discharge through menu temperature discharge dialysis or standby mode (analogue valve)

When an adjustable start temperature has been reached in the permeate (factory setting: start 35°C / stop

33°C), the system discharges the concentrate via

Y9

depending on

LSHL2

until the temperature drops to

below the stop value.

6.2.11.2 Discharge via alarm evaluation (digital signal)

When the limit temperature set on the temperature limit value controller has been reached, the system

discharges the concentrate via Y9 depending on LSHL2 until the temperature drops below the limit value.

The message “Alarm 21, temperature too high” appears on the display.

6.2.11.3 System stop via error evaluation (digital signal)

When the set limit temperature is exceeded for more than 3 minutes (alarm 21), the system switches off

(consumer protection).

IMPORTANT The Hydrowatch must be checked before and after each chemical disinfection. If the red

indicator is visible, the loop must not be disinfected.