LAUNCH

Installation Instruction for Economical Symmetric Floor-plate 2-post Lift

8

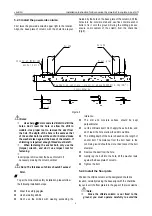

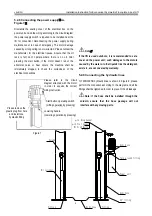

5.2.8 Connecting the power supply

(

As

Figure 7

)

Dismantle the sealing cover of the electrical box on the

power unit and do the wiring according to the circuit diagram;

the power supply switch is required to be installed near the

lift for convenient disconnecting the power supply during

maintenance or in case of emergency. The motor damage

caused by wrong wiring is not warranted. Please contact the

manufacturer for the electrical issues. Ensure that the oil

tank is full; don’t operate where there is no oil. After

pressing the start button, if the motor doesn’t run or the

abnormal noise or heat occurs, the machine shall be

immediately stopped to check the correctness of the

electrical connections.

Figure 7

Note

:

If the lift is used outdoors, it is recommended to set a

cover on the power unit; such damages to the motors

caused by the water or other liquids like the detergent,

acid, etc, are not covered by warranty.

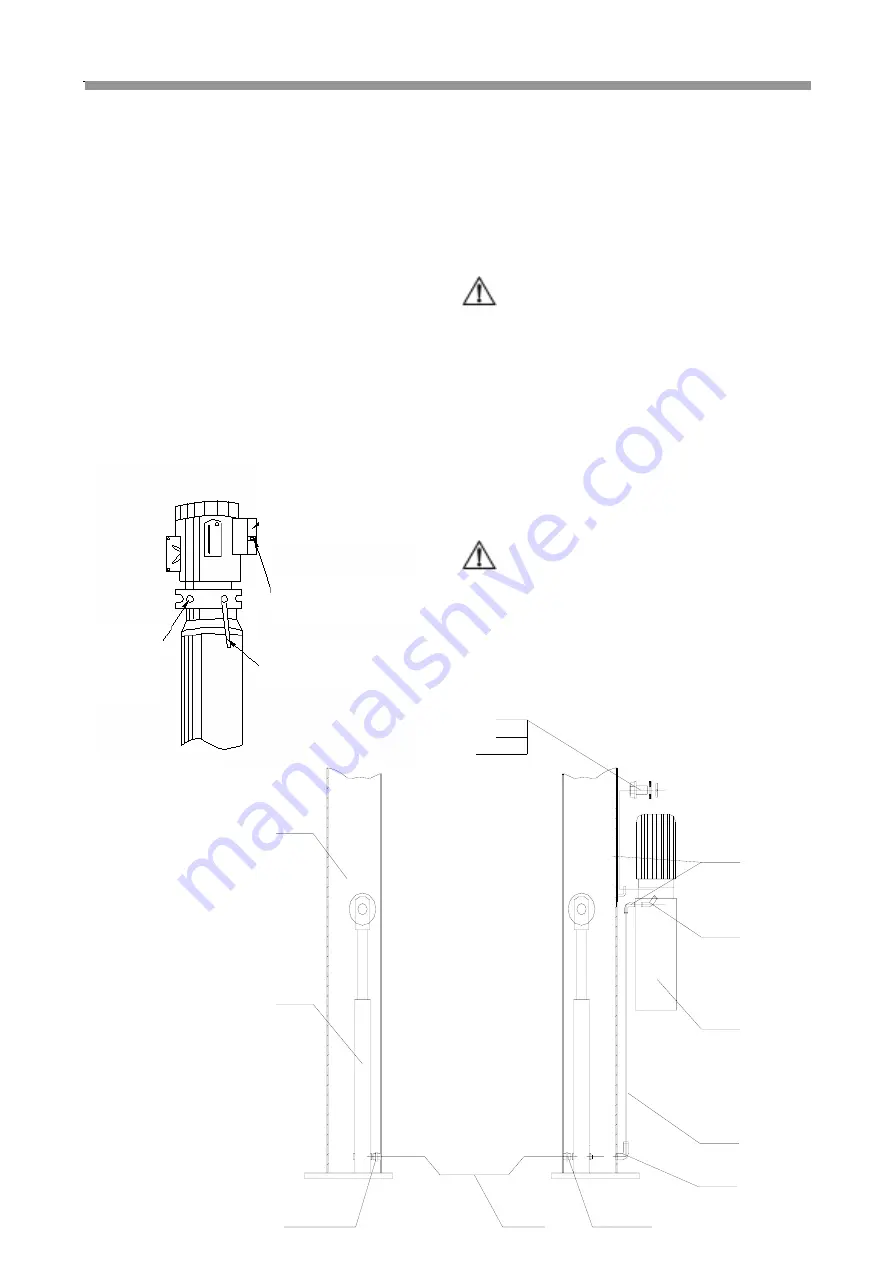

5.2.9 Connecting the hydraulic lines

TLT235/240SB hydraulic lines is shown in Figure 8; please

perform the connection according to the diagram and all the

fittings shall be tightened in order to prevent the oil leakage.

Note: If the hose shall be installed through the

column, ensure that the hose passage will not

interfere with any moving parts.

Please remove the

plastic plug from here

and install one

hydraulic fitting

Start button operating switch

(Lifting operation by pressing)

Lowering handle

(Lowering operation by pressing)

Please refer to the circuit

diagram attached with the motor

in order to acquire the correct

wiring instruction.

Fitting

Oil cylinder

Column

Hydr hose

90

°

fitting

Fitting

Power unit

Hydr hose

M10

×

25 Bolts

2 sets

φ

10 Ring gasket

φ

10 Flat gasket

Hydr hose

Turn around fitting