LAUNCH

440(440W) 455(455W) Installation Manual

18

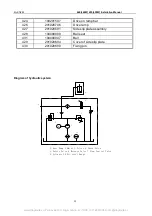

6. Adjustment

6.1 Preparation

l

Lubricate all moving parts of the lift.

l

Fill the N32 or N46 hydraulic oil into the tank of power

unit.

6.2 Adjustment procedure

l

Check the power supply for motor.

l

Check the compressed air supply.

l

Check for the tightness of all the connecting bolts.

l

Press the start button on the power unit, and the

runway will go up; stop pressing the button, then the

lift will stop. For lowering the lift, if the locking latches

are engaged, lift must be raised enough for all 4

latches to clear the latch plate slots inside the columns.

Actuate the air control valve to disengage all the 4

locking plates and push the lowering handle on the

power unit to lower the lift.

l

When the vehicle is lifted up to the required height,

first press the lowering handle to actuate the safety

latches in order to ensure the safety service of vehicle.

l

Adjust the horizontal position of the two runways; use

the wrench to unscrew the locking nuts of the

adjusting bolts on the top of four columns; the up and

down positions of the locking latch plate can be

adjusted via the adjusting bolts so as to make the

runways level.

l

There might air in the hydraulic system due to the new

installation. Air bleeding operation can be performed

by lifting and lowering the runways several times.

l

The adjustment is completed.

www.diagtools.eu, Pernavas 43A, Riga, Latvia, LV-1009, +37129416069, info@diagtools.eu