1.3.6.4. Flowmeter

The flowmeter installed on the EVD electronic machines,

measures the quantity of water sent to the brewing unit

for espresso brewing.

The flowmeter generates an electric impulse which is

sent to the electronic control unit.

This impulse is read by the control unit and memorized

during the programming of the dose.

The flashing of the LED (1) indicates that the electrical

impulse has been sent from the flowmeter to the control

unit.

1.3.6.5. Boiler temperature and pressure control

The flowmeter installed on the EVD electronic machines,

measures the quantity of water sent to the brewing unit

for espresso brewing.

The flowmeter generates an electric impulse which is

sent to the electronic control unit.

This impulse is read by the control unit and memorized

during the programming of the dose.

The flashing of the LED (1) indicates that the electrical

impulse has been sent from the flowmeter to the control

unit.

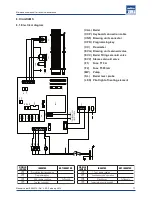

1.3.6.6. Pumping system

It is the component that feeds the machine, raising the

water pressure to 8-9 bars for coffee brewing and auto-

matic filling of the boiler.

To set the pressure rating, proceed as follows:

- select a coffee dispensing key;

- connect a pressure gauge, with bottom scale greater

than 9 bars, to the specific fitting on the water circuit

(see the hydraulic diagram);

- set the pressure by using the pressure adjusting screw

located in the pump (A) in such a way as to reach a

value between 8 and 9 bars: turning clockwise the

pressure increases, turning anticlockwise the pressure

decreases;

- check the pressure on the pressure gauge.

1.3.6.7. Valve group

The valves serve to ensure safety and proper machine

operation.

Safety valve

The safety valve serves to eliminate the air

in the boiler during the heating of the ma-

chine.

Pressure relief valve

The pressure relief valve ensures that the

pressure in the boiler doesn’t exceed 2.2

bars. In case of a malfunction, the capacity

of the valve is likely to eliminate all the ex-

cess pressure in the boiler.

Expansion – one-way valve

This device consists of an expansion valve and a one-

way valve.

Expansion valve: the cold water sent from the pump to

the heat exchangers is heated. This heating causes an

increase in the volume of the water. To limit pressure in-

creases in the hydraulic circuit, the valve limits the ma-

ximum internal pressure in the circuit to 12 bars.

one-way valve: its function is to prevent the backflow of

the water from the exchangers to the hydraulic circuit.

1

X

A

One-way

valve

Expansion

valve

Manual code 10066574 / Rel. 2.00 / February 2012

5

Maintenance manual for technical assistance