Superabrasive

User Manual

Original Language

Lavina® 25-X

9/2018

15

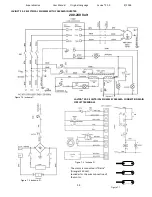

8. TROUBLESHOOTING

INDEX OF PROBLEMS AND SOLUTIONS

8.1 REPLACING POWER CORD AND PLUGS

When replacing the power cord or plugs, always use cords and plugs with the same specifications as the original ones. Do

not use lower quality or different types of cords or plugs.

In addition, consider the distance between the appliance and the electrical source. The greater the distance, the greater the resistance and

the less current that will be available at the other end. This will cause a voltage drop and the inverter will switch into alarm mode. This will

also happen if several machines are working on the same line or the generator is not rated for the power needed. In general, our standard

power cable can be doubled in length; longer lengths require replacing all the cables with cables of a larger gauge rate to account for the

length and amperage.

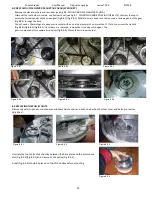

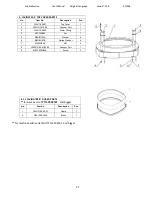

8.2 DISMOUNTING AND MOUNTING TOOL HOLDER TO CHANGING V-RINGS AND FELT-RINGS

To check or replace the buffers and the elastic elements, the tool holders have to be dismounted.

You will need a 13mm deep metric socket with an outside diameter of no more than 3/4in to unscrew the four bolts (Fig.8.2.1) and remove

the holder (Fig.8.2.2). When the tool holder is dismounted, you can change the sealers (V‐Ring and Felt‐Ring).

By loosening four Hex cap flange bolts (Fig.8.2.3) the adaptor comes loose. Unscrew the six screws of the cap (Fig.8.2.4) holding the felt‐

ring. Take out the Felt‐Ring, adaptor and V‐Ring.

Mount the V‐Ring with the smallest lip of the V to the inside (Fig.8.2.5) ‐ simply push the V‐Ring so the top is on the same level as the

pulley top (Fig.8.2.6). Then take the adaptor and push the V‐Ring down with the adaptor (Fig.8.2.7). The lowest lip of the V‐Ring should only

barely touch its gliding surface. Mount the adaptor and the Felt‐Ring on top (Fig.8.2.7). Close the sealers with the cap (Fig.8.2.8) and screw

the bolts. Always use the original bolts. Do not push the V‐ring down with fingers.

8.3 DISASSEMBLING AND MOUNTING TOOL HOLDER TO CHANGE BUFFERS AND ELASTIC ELEMENT

When the TOOL HOLDER is disassembled you can change defective parts – elastic element, buffers, etc.

Lift the locking pin (Fig.8.3.1) to dismount the retaining washer (Fig.8.3.2). Take out the screws on the buffers and the nuts of the elastic

element (Fig.8.3.3;Fig.8.3.4). Remove the elastic element from the QC plate (Fig.8.3.5). While the holder is dismounted (Fig.8.3.6;Fig.8.3.7),

clean the parts and replace any defective ones with new ones. Assemble the holder with new buffers, new screws, and new elastic element.

Replace the retaining washer (Fig.8.3.8) and push the locking pin (Fig.8.3.9). This will prevent the washer from falling while mounting the

holder on the machine.

Figure 71

Figure 71

Figure 8.2.1

Figure 8.2.2

Figure 8.2.3

Figure 8.2.4

Figure 8.2.5

Figure 8.2.6

Figure 8.2.7

Figure 8.2.8