if not clearly indicated that the operation must be

carried out when the machine is on.

•

K2

All the adjustment and activities that are

not described in this handbook must be carried

out by qualified and skilled operators to avoid

any accident or damage to the machine and to

the operator.

•

K3 Carefully read this operating handbook befo-

re use.

It provides important information about a safe in-

stallation, use and maintenance of the machine.

•

K4

The non-compliance with the safety me-

asures may entail serious injuries to the operator

and damages to the machine.

•

K5

Carefully keep this handbook for consul-

tation purposes up to the machine final disman-

tling. The use and maintenance activities must

be carried out correctly; otherwise, the builder

cannot be held responsible for the damages to

people, animals or things deriving from the non-

compliance with the following instructions.

•

K6

Check that both the machine and its com-

ponents are undamaged when unpacking them.

Contact your reseller in case of doubts.

•

K7

Make sure that the rating corresponds to

the factory power line before energising the ma-

chine.

•

K8

De-energise the machine before any cle-

aning or maintenance activity.

•

K9

Never leave the machine energised if

unused. Turn the main switch off.

•

K10De-energise the machine in case of failure

and / or troubles. Do not tamper with its controls

and equipment. Just contact the authorised after-

sales service points for servicing purposes and al-

ways order original spare parts.

•

K11 The draining and loading pipes, the sa-

fety sheaths and the solenoid valves must not be

cut and tampered with. De-energise the machine

in case of damages

•

K12 Any use of the machine other than the

one it has been built for represents an anomalous

condition and can cause serious damages to the

operating means and entail a serious risk for the

operator using it.

•

K13

Never remove or hide the warning labels

applied to the machine.

•

K14 The same instructions are valid for va-

rious models; some details may differ according

to the machine model.

•

K15 Never touch or start the machine with

wet hands or bare feet;

•

K16 Remove the casings and the doors of the

electric boards only once the machine has been

stopped and de-energised;

For fire-prevention purposes:

•

K18

Keep all inflammable or combustible pro-

ducts away from the equipment area.

•

K19

Obviously, the above-mentioned instruc-

tions are not sufficient to prevent all sorts of ac-

cidents; therefore, the user will have to be cau-

tious.

•

K20 The machine must not be modified or chan-

ged in any way without the builder’s written au-

thorisation.

•

WARNING: We recommend the use of demine-

ralized water.

•

WARNING: Never use the power cable or the

gun cable to move it.

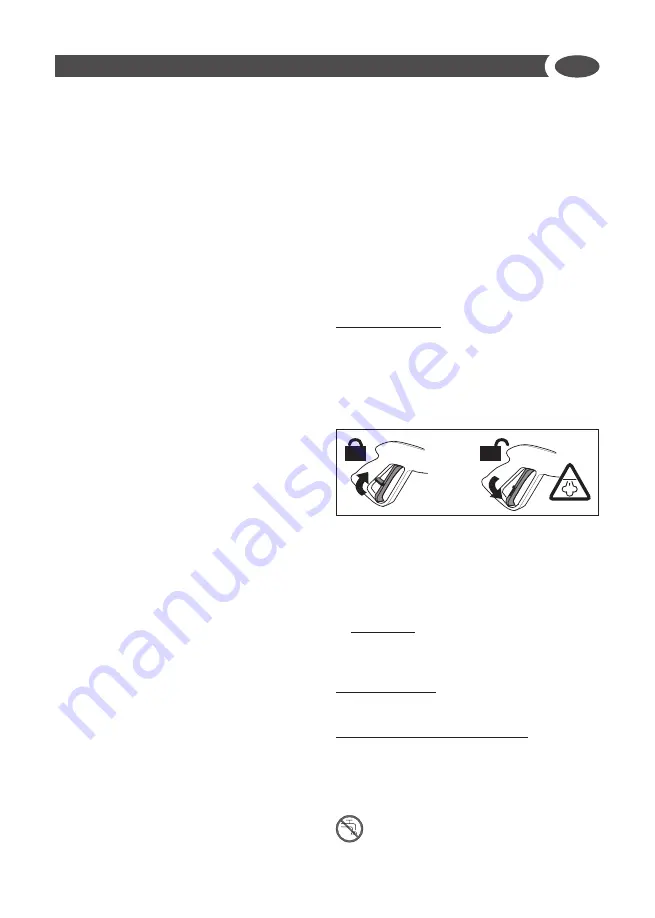

> SAFETY DEVICE

•

WARNING: the gun is fitted with a safety

catch. Whenever use of the machine is

interrupted it is important to operate the

safety catch to prevent accidental activation

of the jet.

Safety features:

- Safety valve

- Manostat

- Thermostat

- Pump with a by-pass valve or stopping device.

> STABILITY

•

WARNING:

The machine must be always kept

on horizontal bases, in a safe and stable way.

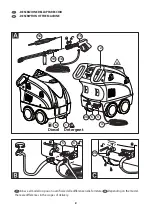

> WATER SUPPLY

Water supply collection

Water supply from the water main

- Connect a supply hose (not included) to

the water inlet of the unit and to the water

supply.

- Open the water supply.

WARNING: (symbol) machine not

suitable for connection to the potable water

EN

15

Summary of Contents for Fuji

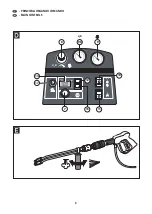

Page 3: ...H2 O H2 O H2 O 9 9b 7 14 17 13 11 10 12 8 PRINCIPALI ORGANI DI COMANDO MAIN CONTROLS E D 3...

Page 22: ...22...

Page 23: ...23...