19

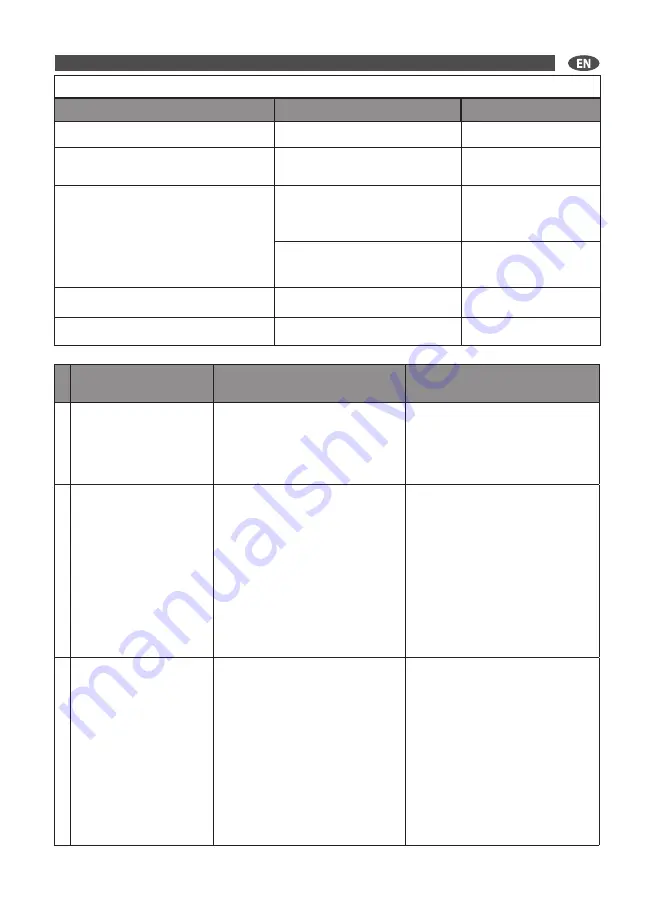

ROUTINE MAINTENANCE TABLE

OPERATION

MACHINE PART

PERIODICITY

Boiler steam blow-off

-

Every day

Boiler cleaning (disassemble the resistors

and remove the limestone)

-

Every year

Visual control

Mac gun

------------------------------------------

Electric parts

Every week

Sealing of the water and steam

con gun

Every mont

Internal cleaning

-

Every year

General cleaning

-

Every week

TROUBLES

CAUSES

SOLUTIONS

1 THE GENERATOR PRESSU-

RE DOES NOT INCREASE

- Resistance contactor

- Pressure switch

- Resistance

- Check the resistance contactor

- Check the pressure switch

- Check the resistance

2 THE PUMP CANNOT RUN

2.1 It loads no water

2.2 Sound allarm

2.3 It does not run

- The water tank is empty

- Pump

- Lack of water in the tank

- water solenoid valve

- Pump

- Water level probe

- Fill the tank

- Replace the pump

- Fill the tank

- Replace the pump

- Check and eventually replace it

- Clean the probe

3 THE SAFETY VALVE OPENS

REPEATEDLY

3.1 It keeps on

loading water

- Boiler water level probe

- Check the electronic level

- Pressure switch

- Resistance contactor

- Safety valve

- Clean the probe

- Replace it

- Replace the pressure switch

and check that the connection

copper tube is free from

incrustations.

- Replace the resistance contactor

- Replace the safety valve

Summary of Contents for GV 8.0 T PLUS

Page 2: ...2...

Page 60: ...60 01 1 02 3...

Page 62: ...62 3PH 400 50 18 8000 W 5 5 9 175 C 62 x 40 x 86 37 39 89 dBA Leq 175 C 80 90 30...

Page 64: ...64 A B A C 1 2 3 1 ON 4 E 5 9 5 I J 1 K 2 3 1 OFF B B M M...

Page 65: ...65 B 3 12 0 5 1 B B 2002 96 EC 27 2003 EC...

Page 66: ...66 1 2...

Page 67: ...67 1 2 2 1 2 2 2 3 3 3 1...