MIXED

COLD

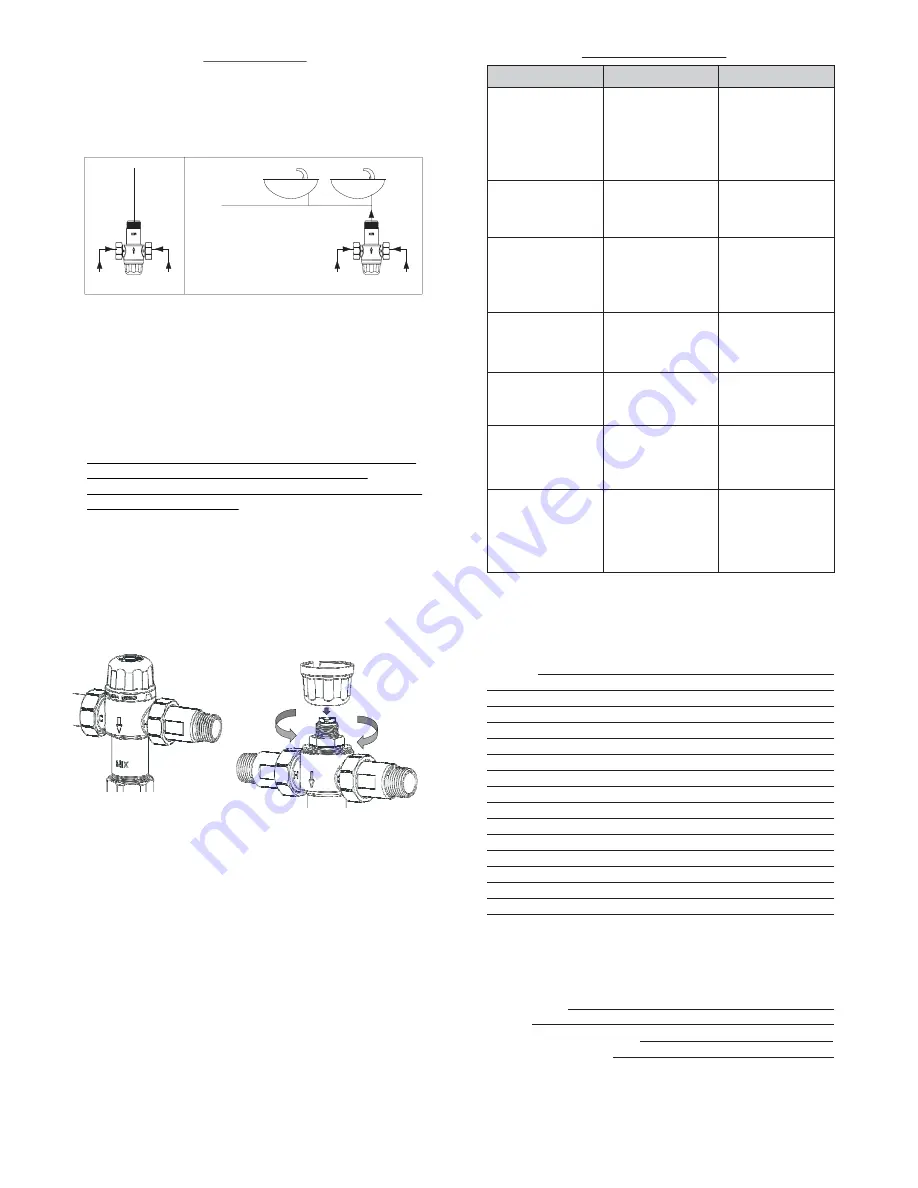

Shower installation

MIXED

COLD

HOT

HOT

Diagram 3 Typical Installations

-

Diagram 4 Valve Adjustment

-

Troubleshooting Guide

FAULT/SYMPTOM

CAUSE

SOLUTION

1. The desired mixed

water temperature

cannot be obtained or

valve is difficult to set.

2. Mix temperature

unstable or changing

over time.

3. Either full hot or full

cold water flowing

from outlet fixture.

4. No flow from the

valve outlet.

5.

Fl

ow

rate reduced or

fluctuating.

6. Mixed water

temperature does

not change when

temperature adjuster

is altered.

7. Valve is noisy.

• Inlet temperatures are

not within specific

limits.

• Hot and cold supplies

are reversed.

• Fluctuating supply

pressures.

• Valve is incorrectly set.

• Hot and cold supplies

are reversed .

• Hot or cold water

supply failure.

• Filter is blocked.

• Fluctuating supply

pressures.

• Filter is blocked.

• Hot and cold supplies

are reversed.

• Excessive water

velocity.

• Valve sized incorrectly.

• Ensure inlet

temperatures are

within the specified

limits for the valve.

• Refit the valve with

Hot/Cold supplies

fitted to the correct

connections.

• Install pressure

regulating valves on

both hot and cold

supplies.

• Adjust mix temperature

as required.

• Refit the valve with

Hot/Cold supplies fitted

to the correct

connections.

• Restore inlet supplies

and check mix

temperature .

• Clean filter .

• Install pressure

regulating valves.

• Clean filter.

• Refit the valve with

Hot/Cold supplies fitted

to the correct connections.

• Reduce water velocity

(best achieved by fitting a

pressure regulating valve).

• Check valve specifications

and ensure the appropriate

valve is used for reguired

flow.

Notes

:

Fitting the Valve

• The mixed water outlet from the valve should be used to supply

outlets used primarily for personal hygiene purposes.

• It is recommended that the valve is installed as close as possible

to the point of use; however , it may be fitted anywhere on the hot

water supply pipe.

TEMPERATURE ADJUSTMENT

• Prior to setting the valve it is necessary for the hot water source to

be switched on and delivering hot water at the designated tempera-

ture .

• Test the mixed water temperature at the nearest outlet being

supplied by the valve. This should be opened to allow a flow rate of

1 to 1.5 gpm (4 to 6 Llmin).

• A thermometer must be used at the nearest outlet to the valve to

ensure the correct mixed water temperature is achieved.

• Allow the water to run for at least one minute to ensure the mixed

water temperature has settled.

• To adjust the mixed outlet temperature of the valve, remove the

cap to gain access to the adjusting spindle. The spindle should be

rotated-clockwise to reduce the temperature, counter-clockwise to

increase the temperature- until the desired set point is reached.

(Refer to diagram 4).

• Once the set temperature is achieved, the cap should be snapped

onto the valve to cover the spindle.

CHECKING / SERVICING THE VALVE

• We recommend that the valve is checked at least once per year to

ensure its continued function. For installations with poor or

unknown water quality, or other adverse supply conditions , it may

be necessary to check the valve at more frequent intervals.

• The temperature should be checked at the same outlet as was

used for commissioning in the first instance. If the temperature is

more than 3°F from the commissioning temperature, refer to fault

finding guide on the next page.

• There may be some variation in the temperature of the water from

the thermostatic mixing valve due to seasonal temperature

variations in the cold water supply.

• If the water supply is of poor quality, a filter or strainer should

be fitted to the system.

Installer, please provide the following information and leave these

instructions with the client.

Installed By:

Date:

Pressure At the Valve:

PSI

Mix Temperature:

F

Multiple Sensor Faucet Installation