23

1

2

3

GENERAL TROUBLESHOOTING

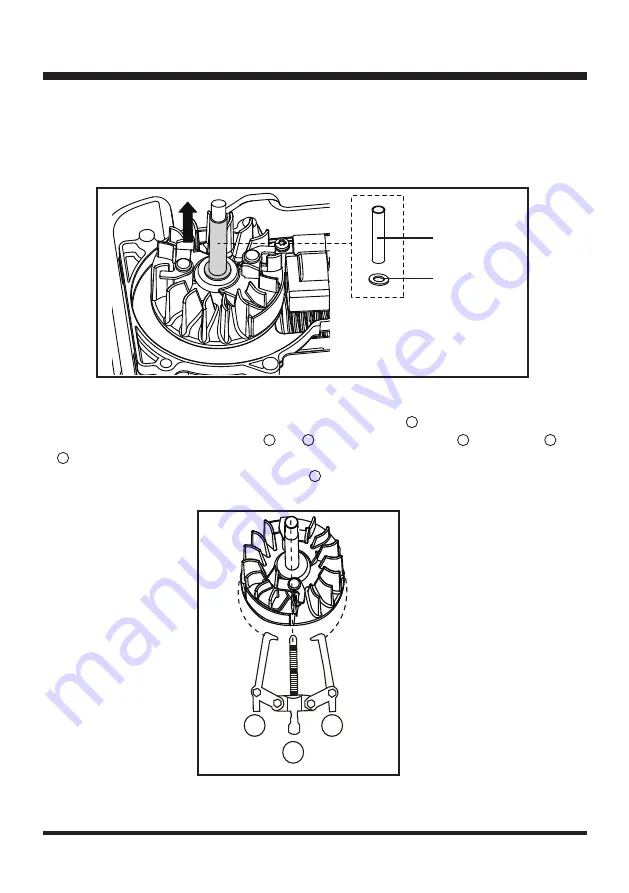

■ The flywheel can be removed by a puller with hooks (Fig. 22). Choose an appropriate puller to

remove the flywheel. Before using the puller, rotate the screw rod

1

counter-clockwise until it is 1/4

to 1/2 its original length. Ensure hooks

2

and

3

are longer than screw rod

1

. Insert hooks

2

and

3

onto both sides of flywheel as shown in Fig. 22. Make sure the hooks are level and with the same

length. Then use a spanner to rotate screw rod

1

clockwise until the flywheel is removed. Rotate

the screw rod counter-clockwise to remove the puller from the flywheel.

Fig. 21

Fig. 22

Flywheel (Rotor) Replacement

(See Figs. 21-25)

■ Remove the rear engine cover, connection cover and front engine cover referring to steps 5 – 9 in

Ignition System section.

■ Remove the flywheel cover assembly and washer (Fig. 21).

Flywheel Cover

Assembly

Washer