crystal standard configuration User Manual

Version: 6.4.0/4

25/149

6. Installation

6.3

Grounding & Power

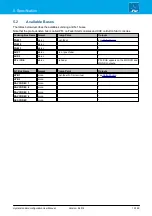

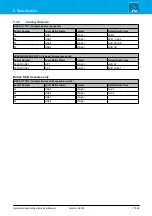

8-fader crystal surface (top edge)

Compact Engine (rear view)

6.3.1

Grounding

Although operator protection is guaranteed, it is best to establish an additional ground for EMC reasons.

On the Compact Engine, a grounding screw is provided beside the

DC IN

connector on the rear of the frame.

On the control surface, a grounding screw is provided beside the

CAN

bus connector.

In each case:

1.

Use the M4x8

CASE

screw to fasten the grounding cable to the housing.

The Compact Engine and Control Surface must be on the same potential as all other system devices.

For Scandinavian countries, ALWAYS use a grounded mains connection, to prevent the device from being

grounded through Ethernet or other signal connections.

Grounding of Audio Interfaces

For compliance with AES3, digital interfaces should be connected to a field ground.

For microphones, the ground from the device should connect directly to the microphone via the cable shielding,

otherwise phantom power cannot be transferred. Take care that the shielding does not connect to the field

ground, to prevent interference and loss of signal quality.

6.3.2

Control Surface Power

The control surface comes with a single power feed: DC.

It is powered by its own external 12V DC power supply. For dimensions, weight and electrical specification,

please see the

Ø

To connect DC power to the surface:

1

.

Connect the 12V DC power supply to the

DC IN

connector on the rear panel.

2

.

Using the IEC cable provided, connect your AC mains to the PSU.

The AC mains connection

MUST

be made using the power cable supplied with the system.