Defender Press Brake Guarding System Operation Manual

LS-CS-M-069

Page 20

Original Language Version: 1.04

Released:

01/04/2020

5.4.1

Status and Action Windows

The Status window informs the operator of the current status of the Defender system, and

the machine it is guarding. The information provided by the Status screen includes:

•

Operating Mode

. The guard mode currently selected (Normal, Tray, Tray 2, Field

Muted) is displayed during normal operation. This message will be overwritten if an

error/fault condition occurs.

•

Mute Status

. The Status window turns red whenever the guarding is muted, to clearly

indicate to the operator that guarding is inactive.

•

Error/Fault Messages

. If the Defender system detects an error or fault condition the

operator will be alerted by the Status window. In most cases this will be a short

message that describes the error/fault condition.

•

Condition Code

. The PGS-2 Safety Controller displays Condition Codes on its

scrolling LCD panel to communicate actions, errors or faults. These codes are

displayed as a 4-digit hexadecimal code (numbers 1-9, letters A-F) that uniquely

describes a particular condition. This Condition Code is also displayed in the lower

right hand corner of the Status window.

•

Operation Pending

: If the PGS-2 Safety Controller requires that an operation is to

be performed to verify the safety performance of the machine (such as an over run

test) the operator is informed of the upcoming operation in the Status window (and is

also prompted for action by Action window message).

The Action window prompts the operator with the action required to complete the current

operation. For example, if a fault condition occurs, the error message and condition code are

displayed in the Status window, while the Action window prompts the operator to

PRESS

RESET

.

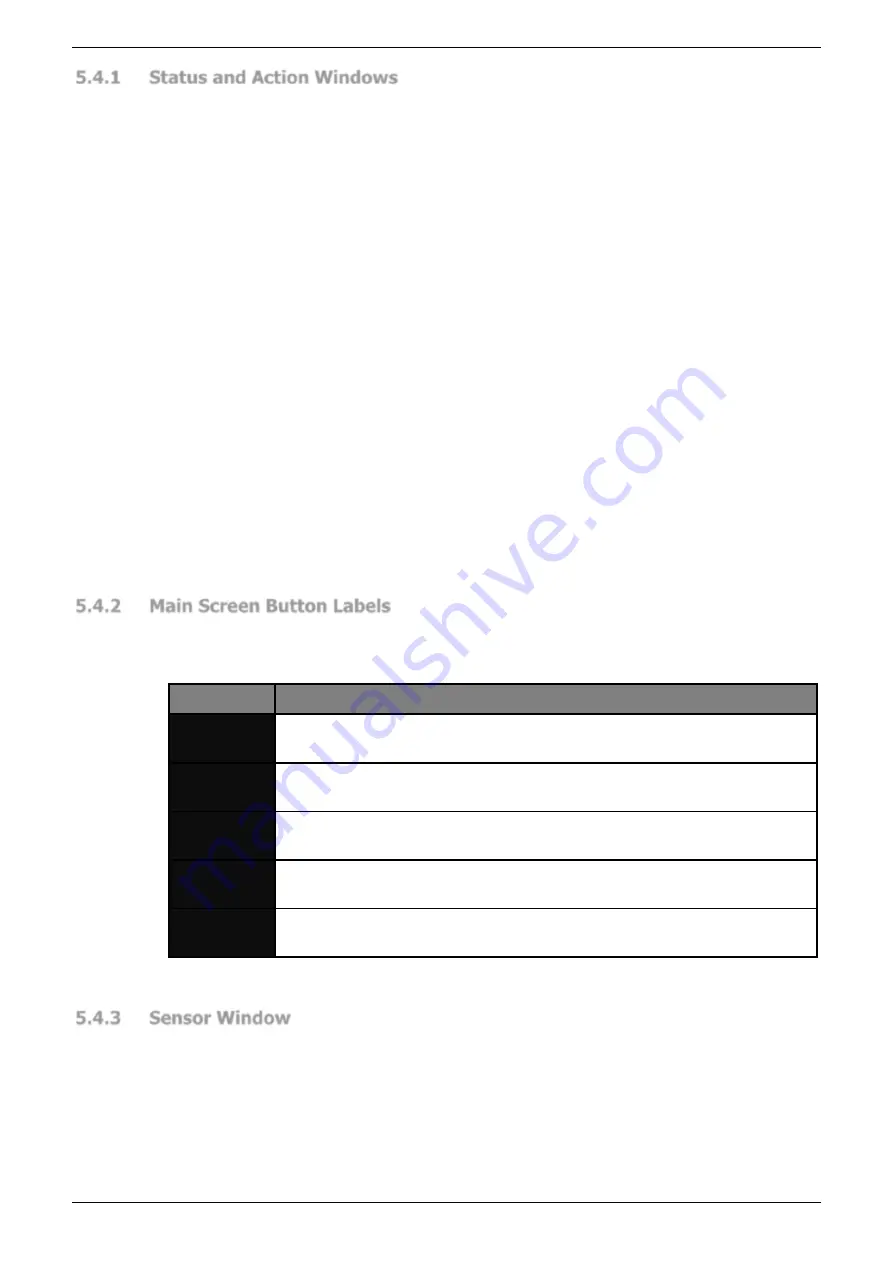

5.4.2

Main Screen Button Labels

The five buttons on the User Interface Panel change function depending upon the current

screen, the Supervisor menu configuration, and the state of the machine. The button labels

for the Main screen are shown in

Label

Button Function

MENU

This leaves the Main screen and enters the Menu screen. See

for an overview of the menu system.

TOOL

SETUP

Leaves the main screen and enters the Tool Setup screen (an access

code is required to enter the Tool Setup screen).

MODE

SELECT

Leaves the Main screen and enters the Mode Select screen, where the

guard modes can be selected.

SET/MUTE

RESET

This button can be used to set or reset the mute point. The button label

changes depending upon the state of the mute point.

INFO

This leaves the main screen and enters the Info Screen. See

for an overview of the menu system.

Table 5-1: Main Screen Buttons

5.4.3

Sensor Window

The Sensor window shows the status of the optical protection from the point of view of the

receiver (the front sensor is to the left of the screen). Symbols in the window show the current

active mode, and the state of the receiver sensors in real time. The general appearance of

the window is shown in

In the following sections the Sensor window will always be shown with the appropriate

symbols for the operating mode being described.