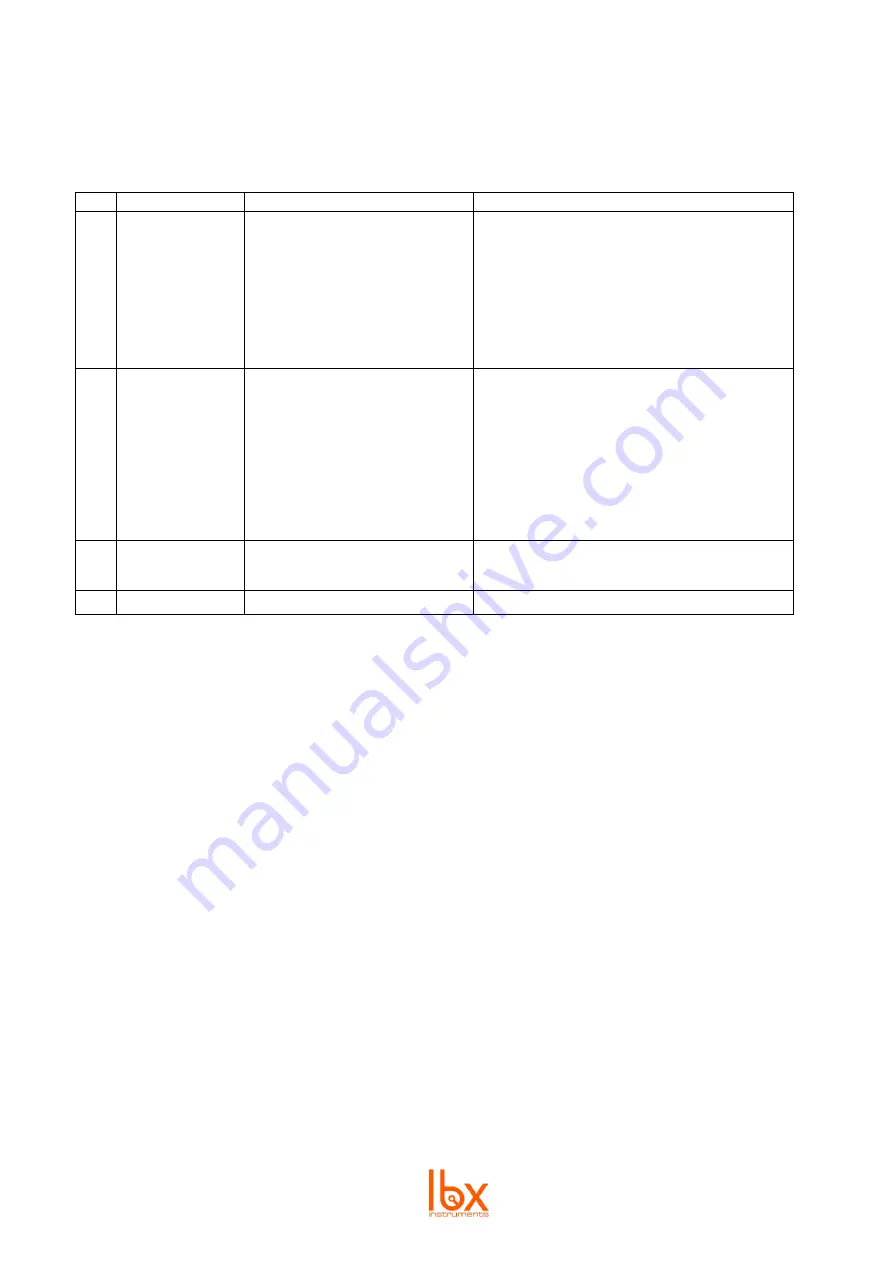

6

4.

Maintenance

•

Regular maintenance, electrical control system with high pressure air blow off the dust.

•

Clean the tank at least once a week

Trouble clearing

No.

Problems

Possible Cause

Solutions

1

No ultrasonic

activity

A.

Power supply not connected

B.

Fuse broken

C.

Cable is short circuited

D.

Transducer is short circuited

E.

PCB Board broken

F.

Other reasons

A.

Check and plug power switch

B.

Check the fitted power supply and change

the same specification fuse

C.

Connect fitted cable or replace a new

D.

Consult with your supplier

E.

Check the broken part and change it

F.

Consult with your supplier

2

Not well

cleaning

A.

Not strong ultrasonic

cleaning

B.

Too high or too low liquid

surface

C.

Too high too low

temperature

D.

Not suitable cleaning liquid

E.

Other Reasons

A.

Connect ultrasonic button and adjust

B.

Adjust liquid into the best surface

C.

Adjust the temperature into the most fitted

D.

Stop and switch off power supply, replace

suitable liquid after previous liquid

cooling down

E.

Consult with your supplier

3

Electric Leakage A.

Customer side not grounded

B.

Machine not grounded

A.

Ensure it is grounded

B.

Check if machine earth wire loosens

4

Other problems

Consult with your supplier

Summary of Contents for ULTR Small

Page 18: ...www labbox com ...