-4-

UDOS 51E

–

Operator’s

Manual v1.6

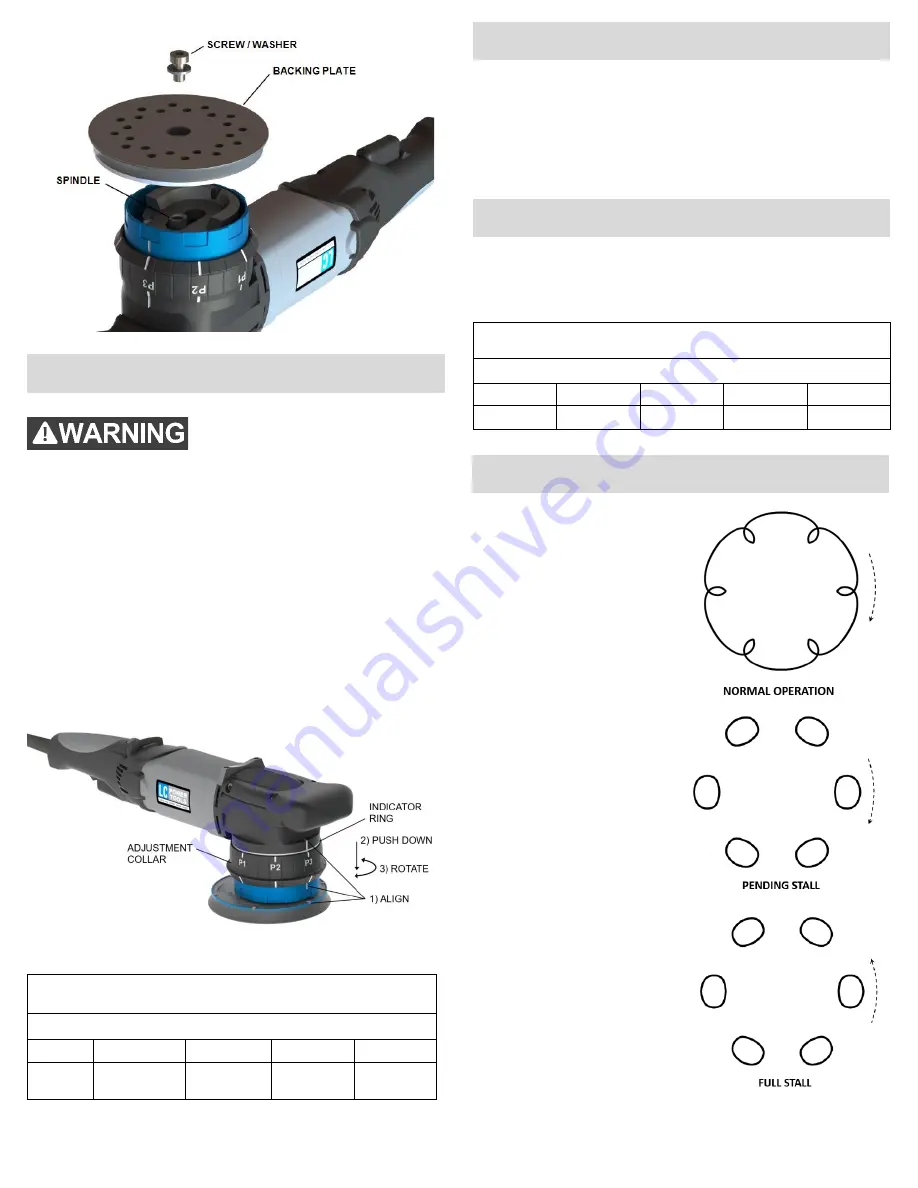

To reduce the risk of injury, it is

recommended to unplug the

tool before changing modes.

1)

Position the tool with the pad facing down resting on

a surface.

2)

Rotate the hub to align one of the two lines to the

white line on the tool body

3)

If going from a DA setting to Rotary, align any one of

the white Stall-Aware® markings on the backing plate

to the aligned lines in Step 2.

4)

Push the adjustment collar down and rotate into the

desired mode.

5)

Release the adjustment collar allowing it to move

upward. Note: Ensure the lock indicator ring is NOT

visible.

UDOS MODE SETTINGS

Adjustment Collar Position

R

S

P1

P2

P3

Rotary

Sand

(8mm DA)

12mm

DA

15mm

DA

21mm

DA

The tool is equipped with load sensing. If an overload

condition occurs, the motor will stop pausing for about 1-

2 seconds, then try to restart. If after 6 restarts the

overload condition still exists, the motor will shut down.

Release the trigger, and allow the tool to cool for 3

minutes before continuing.

The rotational speed of the tool is adjusted using the

scroll thumb wheel on top of the handle. The following

table provides the approximate spindle RPM for each

setting of the thumb wheel.

The 6 white Stall-Aware®

marks on the top of the

UDOS

backing

plate

provide

a

convenient

indication of the orbital

rotation of the pad. During

normal

operation

the

Stall-Aware® markings will

rotate

clockwise

and

appear similar to the

pattern shown.

Applying more pressure

will cause the pattern to

shift to a series of clockwise

rotating circles as shown,

indicating a

pending stall

.

If excessive downward

pressure is applied, the

circle pattern will appear to

stop then rotate counter

clockwise, indicating a

full

stall

. Decrease the pressure

on the tool to restore proper

orbital action.

APPROXIMATE ORBIT SPEED (Orbits/minute)

Thumb Wheel Setting

1

2

3

4

5

1000

1350

1700

2050

2400

MODE SELECTION

OVERLOAD PROTECTION

SPEED ADJUSTMENT

STALL-AWARE

®