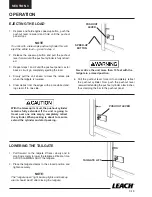

OPERATION

SECTION 3

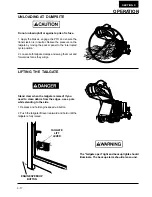

Do not operate a unit that is in need of service

or repair.

15. Report any problems found during the pre-opera-

tion walk-around inspection to the maintenance

supervisor for service or repair, place a tag on the

steering wheel, using a non-reusable fastener,

stating the unit is inoperative and remove the keys.

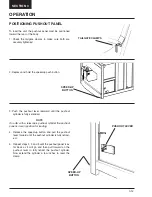

WALK-AROUND INSPECTION

CHECKLIST

1. Decals in place and readable.

2. Look for any fluid leaks.

3. Mounting hardware tight and in place.

4. Tailgate clamps closed and tightened.

5. Hydraulic fluid reservoir at correct level.

6. All operating levers in neutral positions.

7. Pushout panel area clear of debris.

8. Engine warmed up according to manufacturer’s

instructions.

9. All operating and running lights functioning.

10. Engine speed-up buttons operational.

11. Packing cycle operates properly.

12. Driver signal alarm can be heard.

13. Back-up alarm and tailgate ajar light are operable.

14. Report any problems to proper personnel.

3-10

Summary of Contents for 2R-II

Page 1: ...2RII PACKMASTER OPERATORS MANUAL Over Serial Number 16000 BUILDING THE BEST...

Page 2: ......

Page 11: ...1 6 SAFETY PRECAUTIONS SECTION 1 1 4 2 5 6 3 7 8 9 10 7 7 9 1 8 4 5 2 6 10 1 3 1 6...

Page 12: ...SAFETY PRECAUTIONS SECTION 1 2 1 3 4 5 1 2 3 4 5 1 7...

Page 14: ...SAFETY PRECAUTIONS SECTION 1 11 12 13 14 15 16 17 18 19 20 21 22 23 1 9...

Page 16: ...SAFETY PRECAUTIONS SECTION 1 1 11...

Page 17: ......

Page 25: ......

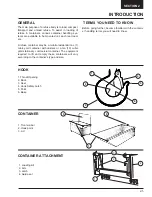

Page 27: ...OPERATION SECTION 3 LOCATION OF OPERATING CONTROLS 1 2 3 8 9 10 11 12 7 4 5 6 7 8 3 2...

Page 46: ......

Page 48: ......

Page 49: ......