OPERATION

SECTION 3

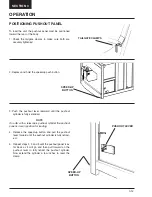

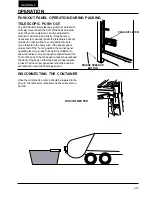

USING A CONTAINER PUSH BAR (CPB)

Once the container is secured within the latch assem-

bly the container is ready to be dumped. After assuring

that all persons are standing clear, the operator moves

the CPB control lever in the direction shown on the in-

struction decal to raise the container. When raiseing a

container with the push bar, it is normal for the container

to first lift upward within the container latch assembly,

then tip toward the hopper and finally lower or drop to the

bottom of the latch slots.

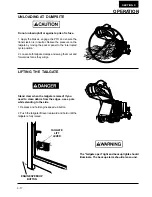

Do not overfill the hopper. After assuring that all persons

are standing clear lower the container to check the load

condition of the container and the hopper. Lower the con-

tainer enough to see between the container and the tail-

gate while standing on the ground without placing your-

self between them.

Releasing the CPB control handle when the container

begins to tip will allow the container trunnion bar to lower

within the latch slots with ease.

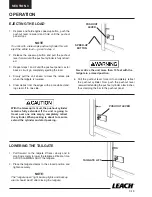

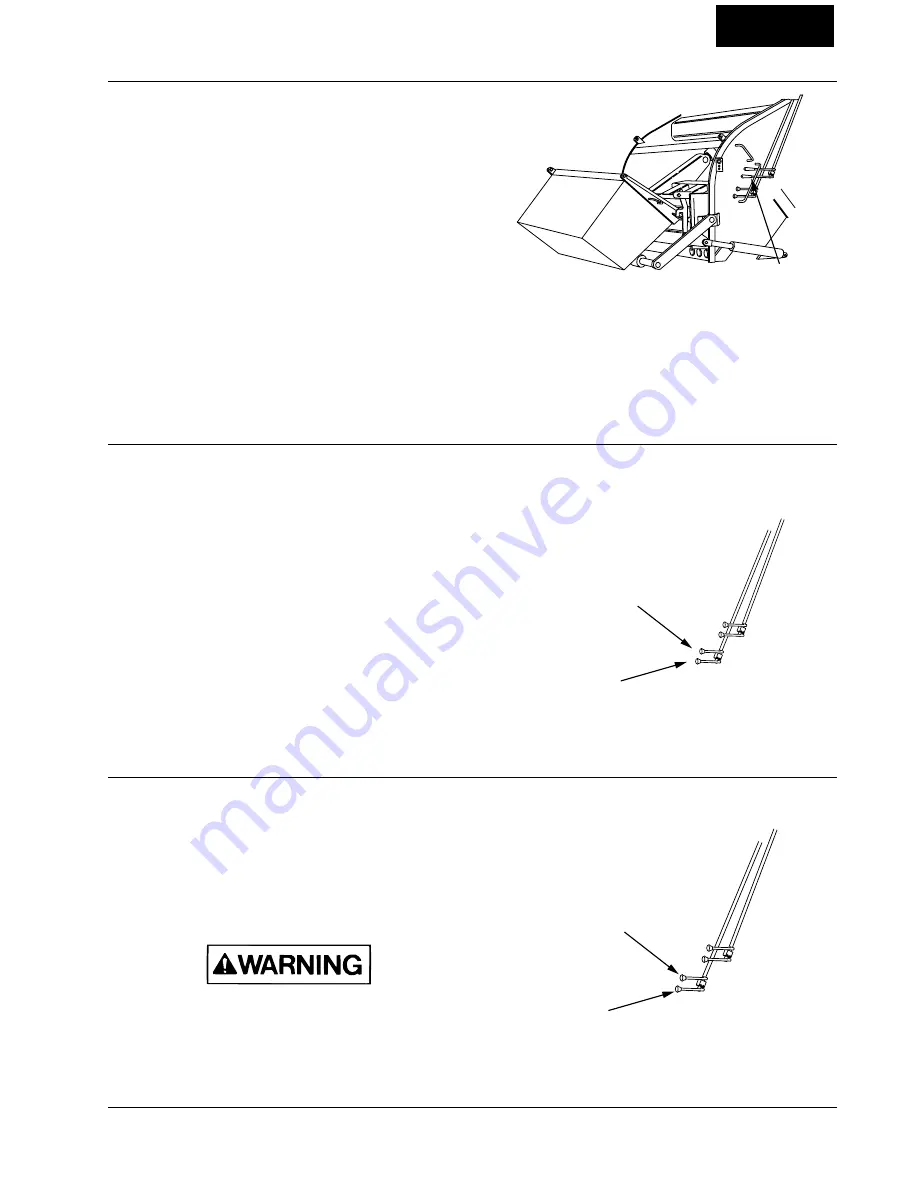

PACKING THE LOAD

NOTE:

The compaction cycle can be stopped at any time by

moving both the packer panel lever and the carrier panel

lever to the center (neutral).

1. Cycle the packer panel and the carrier panel by mov

ing both the packer panel lever and the carrier panel

lever inward, toward the tailgate, then let go. The packer

panel will open and the packer panel lever will automati-

cally shift to neutral. The carrier panel will then move

down to above the loding edge, stop in the interrupted

cycle position and the carrier panel lever will automati-

cally shift to neutral.

2. To finish the cycle, move both the packer panel lever

and the carrier panel lever outward, away from the tail-

gate, then let go. The packer panel will sweep the hop-

per and the packer panel lever will automatically shift to

neutral. The carrier panel will then move up into the body

and stop in the home position and the carrier panel lever

will automatically shift to neutral.

Stand clear of the hopper area during the packing

cycle!

3. Repeat steps 1 and 2 each time the hopper is filled to,

but not above, the loading edge.

CONTAINER

CONTROL

LEVER

PACKER PANEL

LEVER

CARRIER

PANEL

LEVER

PACKER PANEL

LEVER

CARRIER

PANEL

LEVER

3-15

Summary of Contents for 2R-II

Page 1: ...2RII PACKMASTER OPERATORS MANUAL Over Serial Number 16000 BUILDING THE BEST...

Page 2: ......

Page 11: ...1 6 SAFETY PRECAUTIONS SECTION 1 1 4 2 5 6 3 7 8 9 10 7 7 9 1 8 4 5 2 6 10 1 3 1 6...

Page 12: ...SAFETY PRECAUTIONS SECTION 1 2 1 3 4 5 1 2 3 4 5 1 7...

Page 14: ...SAFETY PRECAUTIONS SECTION 1 11 12 13 14 15 16 17 18 19 20 21 22 23 1 9...

Page 16: ...SAFETY PRECAUTIONS SECTION 1 1 11...

Page 17: ......

Page 25: ......

Page 27: ...OPERATION SECTION 3 LOCATION OF OPERATING CONTROLS 1 2 3 8 9 10 11 12 7 4 5 6 7 8 3 2...

Page 46: ......

Page 48: ......

Page 49: ......