SAFETY PRECAUTIONS

SECTION 1

OPERATION

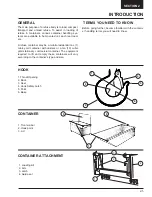

GENERAL

1. It is the operator’s responsibility to ensure that

operation of the unit is in accordance with the

guidelines contained in the Operator’s manual and

in accordance with all applicable codes including

Occupational Safety and Health Act (OSHA) and

American National Standards Institute (ANSI) reg-

ulations.

2. Do not attempt to operate this equipment without

proper training.

3. Move the vehicle as slowly as possible without

stalling when traveling in reverse.

4. Always make sure the area behind the unit is clear

before traveling in reverse.

5. Do not travel in reverse for distances greater than

those dictated by local ordinances. If reverse trav-

el exceeds 10 feet, use a “spotter” or move the

vehicle in 10 foot increments only, and then check

to make sure the area behind the unit is clear

between increments.

6. Do not attempt to dislodge any material above

waist level unless wearing eye protection such as

“approved” side shielded safety glasses or a full

face shield.

7. Never use the unit to push or tow another vehicle.

8. Never unload uphill or against a pile of refuse or

into the bank of a hill.

9. Never place head, body, fingers or any limbs into a

scissors point or pinch point on the equipment.

10. Before operating the vehicle the driver must be

thoroughly familiar with the employer’s safety pro-

gram concerning traffic rules, warning devices and

hand signals.

11. Know where to get assistance in the event of an

emergency.

12. Know your machine. Know the location and func-

tion of all controls, gauges, instruments and pro-

tective devices.

13. Wear your seat belt.

14. Start the engine following the manufacturer’s rec-

ommended procedure.

15. Always set the parking brake before leaving the

cab.

16. Turn on appropriate warning lights, put on a safety

vest, protective glasses and protective shoes.

17. All service opening covers and access doors must

be maintained and latched in place while operating

equipment.

18. Ensure all co-workers are in view before operating

or moving any controls or the unit.

19. Ensure that there is sufficient overhead clearance

before operating the unit.

20. Ride only in the cab or on riding platforms

designed for that purpose. Riding steps shall not

be used when speeds are expected to exceed 10

mph or when distance traveled without stopping

will exceed

2

⁄

10

of one mile. Do not mount or dis-

mount riding step when vehicle is in motion.

21. Never allow anyone to ride on the steps when the

vehicle is backing up.

22. Stop the vehicle immediately if warning lights for

the TAILGATE AJAR system come on.

23. Never use controls or hoses for hand holds when

mounting or dismounting. Controls and hoses are

movable. They do not provide proper support and

may cause accidental equipment movement.

24. Make sure the backup alarm is working properly.

25. Always ensure that all persons are clear before

raising or lowering the tailgate. It is the operator's

responsibility to warn all persons not to stand or

cross under a raised tailgate.

26. Do not move the vehicle with the tailgate raised

except during unloading and then only as neces-

sary to clear the load before lowering.

27. Stand clear when the tailgate is being raised or

lowered and during the unloading cycle. If it is nec-

essary to manually clear debris from the hopper,

use a long metal probe and DO NOT stand under

the tailgate.

28. Never load the hopper above the loading sill.

29. Never allow material to extend outside of the hop-

per when packing.

30. Allow the packer panel control lever and carrier

panel control lever to shift automatically.

31. To avoid possible bodily injury or equipment dam-

age, lower the tailgate slowly.

32. Never enter the body unless the pushout panel

clamp or the telescopic ejection system cylinder is

released, PTO disengaged and ignition key

removed and placed in your pocket.

33. Do not attempt to load refuse into the hopper after

1-3

Summary of Contents for 2R-II

Page 1: ...2RII PACKMASTER OPERATORS MANUAL Over Serial Number 16000 BUILDING THE BEST...

Page 2: ......

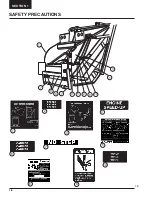

Page 11: ...1 6 SAFETY PRECAUTIONS SECTION 1 1 4 2 5 6 3 7 8 9 10 7 7 9 1 8 4 5 2 6 10 1 3 1 6...

Page 12: ...SAFETY PRECAUTIONS SECTION 1 2 1 3 4 5 1 2 3 4 5 1 7...

Page 14: ...SAFETY PRECAUTIONS SECTION 1 11 12 13 14 15 16 17 18 19 20 21 22 23 1 9...

Page 16: ...SAFETY PRECAUTIONS SECTION 1 1 11...

Page 17: ......

Page 25: ......

Page 27: ...OPERATION SECTION 3 LOCATION OF OPERATING CONTROLS 1 2 3 8 9 10 11 12 7 4 5 6 7 8 3 2...

Page 46: ......

Page 48: ......

Page 49: ......