108 Service & Repair

4.

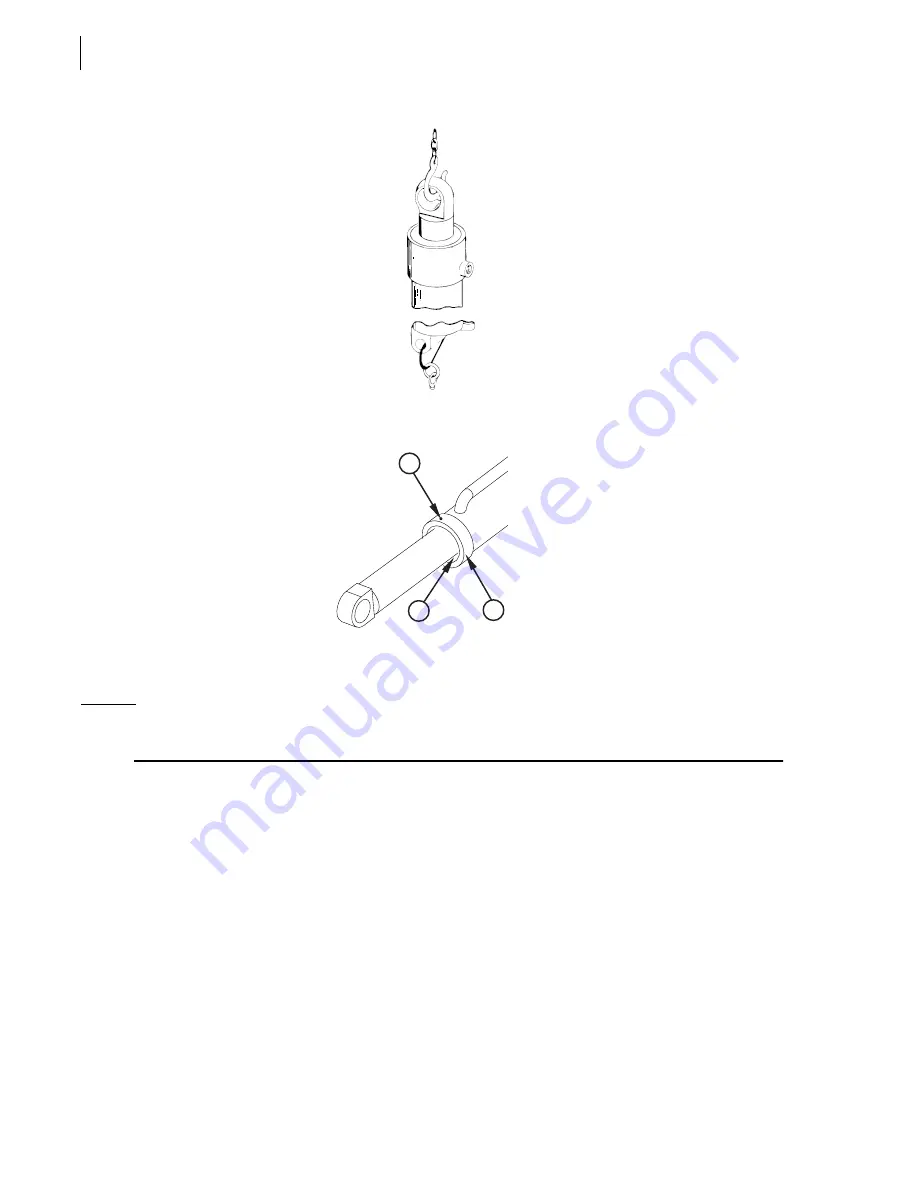

Remove the set screw (1) securing the gland nut

(2) to the gland (3).

5.

Slowly operate the hoist to carefully pull the piston rod assembly out of the cylinder.

6.

Disassemble the cylinder and install replacement part(s).

N

OTE

:

During disassembly note the condition of each part as

it is removed to aid in diagnosing. Note

the position of

each part as it is removed to aid in reassembly.

Inspection and Replacement of Operating

Cylinders

For these tasks, apply the following procedure:

1.

Carefully and thoroughly inspect the inside of the

cylinder for cracks, scoring or uneven wear.

Check

all parts for damage.

2.

A new rod wiper (1), rod seal (2), o-ring and back

up ring (3), seal (4), wear rings (5) and piston

seal (6) must be installed any time the cylinder is disassembled. Pay particular attention to the

way parts are positioned for correct assembly. Parts that must be replaced together are available

as a repair kit

from your authorized Leach distributor.

1

2

3

Summary of Contents for 2R-III

Page 1: ...2R III MAINTENANCE MANUAL...

Page 2: ......

Page 3: ...2R III MAINTENANCE MANUAL...

Page 5: ......

Page 6: ......

Page 20: ...10 Introduction...

Page 42: ...32 Safety...

Page 58: ...48 Preventive Maintenance Figure 5 1 Hydraulic tank w return filter 1 2 3 4 5 6 7 8...

Page 66: ...56 Preventive Maintenance...

Page 102: ...92 Troubleshooting...