Service & Repair 121

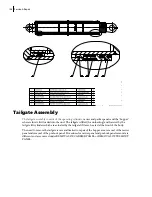

The purpose of adjusting the carrier panel wear shoes (see Figure 8-3) is to provide for smooth

upward and downward travel of the carrier and packer panels with a minimum of side travel. In

essence, the wear shoes are adjusted to align the carrier panel to the carrier operating cylinder stroke

positions, and by shimming the wear shoes in a diagonal fashion, the carrier may be adjusted to allow

for fabrication variances of the many components of the tailgate assembly.

Figure 8-3

Wear shoes

Wear shoes are to be adjusted by the use of shims (part #186536) placed behind the Teflon plastic

plates (see Figure 8-2). This will allow the wear shoes to either be moved outward by the addition of

shims, or moved inward by the subtraction of shims. It should be noted that the shims are used only

as required; there is no set amount of shims per wear shoe.

However, over-shimming of the wear shoes will result in track distortion. The preferred condition of

the wear shoes is to allow them to have a minor amount of side travel in the tracks rather than being

too tight. Proper shimming of the wear shoes will avoid costly damage to the structure of the tailgate.

Diagnostic Procedure

Careful and patient evaluation of the carrier panel in motion is the key to proper adjustment of the

wear shoes. All wear shoes should be lubricated, and the carrier should be completely cycled at least

four (4) times to gain an initial understanding of the side to side play of the carrier on the wear shoe

pins. If this play is causing movement of more than ¼” at the point of the wear shoe(s) when the

carrier operating cylinders are in the fully retracted or extended position, then adjustment is

necessary. Some side to side play of the carrier panel during movement may be considered common.

The carrier panel may be operated in a manner to aid in the determination of adjustment. By turning

the engine speed up system off, then operating the carrier, it is easier to determine movement due to

the slowed speed of carrier. Also, if movement is detected, operate the carrier to a point

approximately 2-4” from full retraction or extension of the carrier operating cylinders. Then, by

“feathering” the control lever, operate the carrier panel until one cylinder is either fully retracted or

extended. At this point, note how far the other cylinder is from this condition. In essence, the carrier

must be square with the carrier cylinders; it does not need to be perfectly parallel with the tailgate

sides.

Summary of Contents for 2R-III

Page 1: ...2R III MAINTENANCE MANUAL...

Page 2: ......

Page 3: ...2R III MAINTENANCE MANUAL...

Page 5: ......

Page 6: ......

Page 20: ...10 Introduction...

Page 42: ...32 Safety...

Page 58: ...48 Preventive Maintenance Figure 5 1 Hydraulic tank w return filter 1 2 3 4 5 6 7 8...

Page 66: ...56 Preventive Maintenance...

Page 102: ...92 Troubleshooting...