4 Introduction

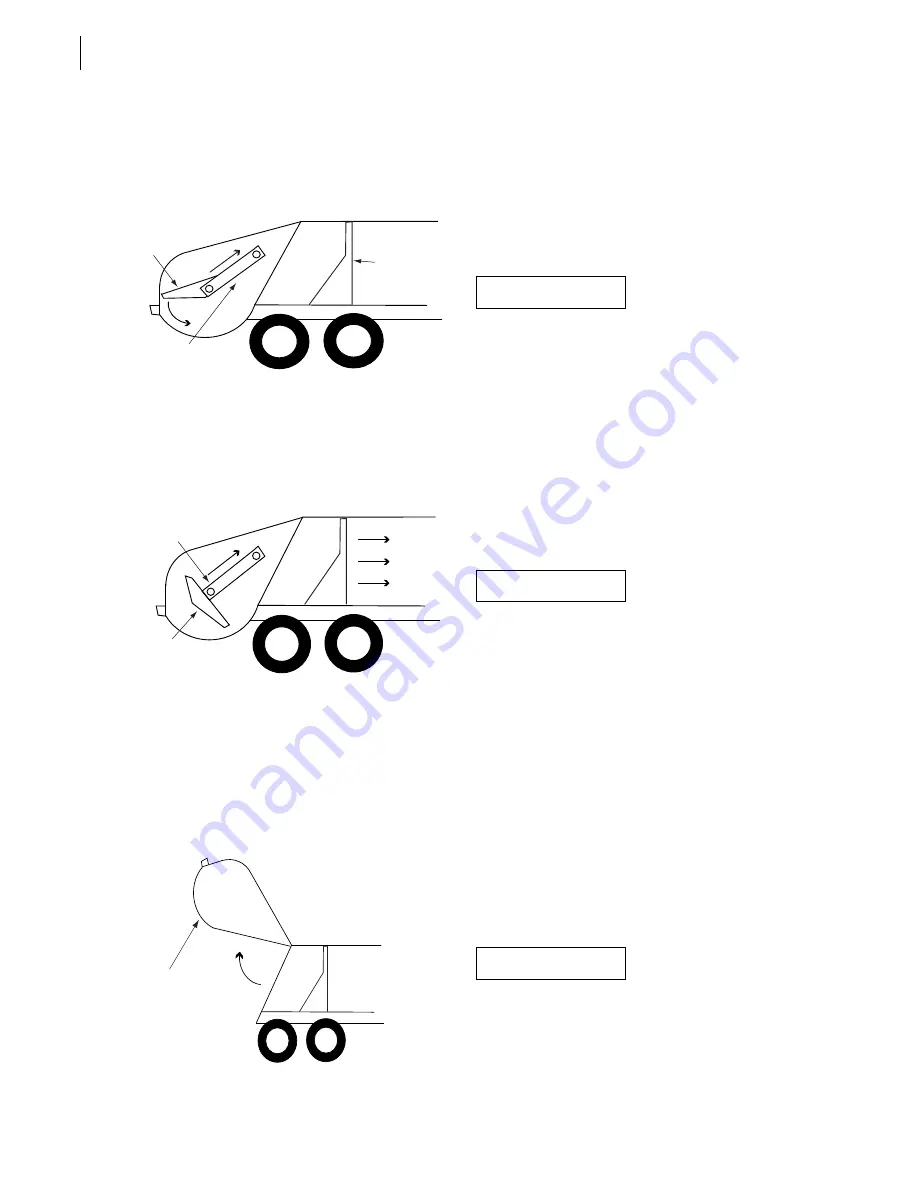

The operator again activates the packing cycle. The

carrier and packer panels move forward and

sweep the refuse from the hopper up into the body and pack it against the pushout panel. Having

completed a cycle, the carrier and packer panels are back into the “home”

position and the hopper is

cleared for more refuse.

Also, during the packing cycle, considerable hydraulic

pressure is applied to the cylinders which

control movement of the carrier and packer panels. This causes the refuse to be compacted tightly

allowing for a large carrying capacity.

Once the body is full, the 2R-III™ can be moved to the dumpsite for unloading.

Unloading

At the dumpsite, the unit is unloaded in two easy steps:

1. The tailgate is raised by the operator.

2. The pushout panel is moved to the rear of the body, pushing out the load.

PA

C

K

ER

PA

NE

L

C

A

RRIER

PA

NE

L

P

US

H

OUT

PA

NE

L

Packing position

PA

C

K

ER

PA

NE

L

C

A

RRIER

PA

NE

L

P

US

H

OUT

PA

NE

L

Pushout panel moves

forward

T

A

I

L

G

A

TE

Tailgate raised

Summary of Contents for 2R-III

Page 1: ...2R III MAINTENANCE MANUAL...

Page 2: ......

Page 3: ...2R III MAINTENANCE MANUAL...

Page 5: ......

Page 6: ......

Page 20: ...10 Introduction...

Page 42: ...32 Safety...

Page 58: ...48 Preventive Maintenance Figure 5 1 Hydraulic tank w return filter 1 2 3 4 5 6 7 8...

Page 66: ...56 Preventive Maintenance...

Page 102: ...92 Troubleshooting...