Troubleshooting 73

Excessive system flow rate (cycle time too fast)

can agitate the hydraulic fluid. Set the cycle time

according to specifications.

Do not thin hydraulic fluid with diesel fuel (lowers

the flash point). Weather permitting, use a

higher

flash point fluid.

After making any repairs on the hydraulic system, bleed

the system at reduced engine speed and

pressure to remove any trapped air. Depending on the size of the component, e. g. cylinder, hose, it

may be necessary to cycle the unit several times. Of course the larger the air pocket, the more cycles

are needed. To avoid potential problems, thoroughly bleed all hydraulic systems and ensure that all

inlet connections are tight and not ingesting

air.

Troubleshooting Tables

Use the following troubleshooting tables to find remedies to problems that have identifiable signs.

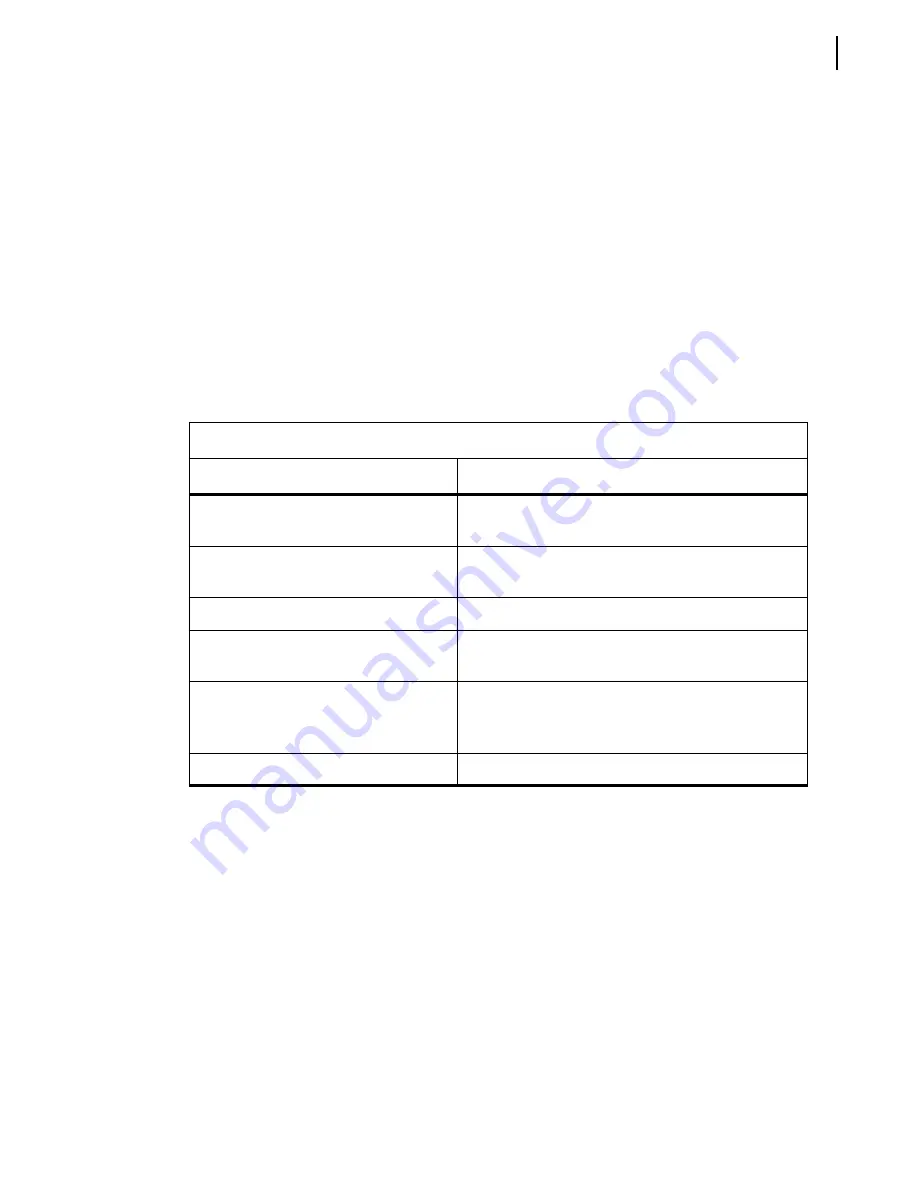

OPERATING IS ERRACTIC

Possible cause

Remedy

Speed up system operating erratically

Check electrical system. See Chapter 8

Service and

Repair

.

Hydraulic fluid too hot

Check for proper grade of fluid (see

Hydraulic fluid level too low

Check fluid level. Add fluid if necessary.

Bypass in cylinders

Test for leaking cylinders. See Chapter 8

Service and

Repair

.

Hydraulic fluid too cold

Bring fluid to operating temperature. Check for

proper grade of hydraulic fluid (see

Operating linkage bent or binding

Repair, replace or realign damage linkage.

Summary of Contents for 2R-III

Page 1: ...2R III MAINTENANCE MANUAL...

Page 2: ......

Page 3: ...2R III MAINTENANCE MANUAL...

Page 5: ......

Page 6: ......

Page 20: ...10 Introduction...

Page 42: ...32 Safety...

Page 58: ...48 Preventive Maintenance Figure 5 1 Hydraulic tank w return filter 1 2 3 4 5 6 7 8...

Page 66: ...56 Preventive Maintenance...

Page 102: ...92 Troubleshooting...