42 Specifications

Pump

Leach Hydraulic Fluid Recommendation

All Leach hydraulic systems are factory filled with a high quality anti-wear hydraulic fluid meeting an

ISO

32

specification. On units put into service where there are high ambient temperatures or

sustained high duty cycles, it may be desirable to change the fluid to an ISO

46 specification (higher

viscosity). In colder climates or light duty, an ISO

22 might be more appropriate. The International

Standards Organization assigns specification numbers so

that a consumer receives the same product

from various suppliers.

Type

Positive Displacement; Gear-Type Driven by the PTO from the

Truck Transmission or by the Engine

Capacity

42 GPM @ 1200 RPM

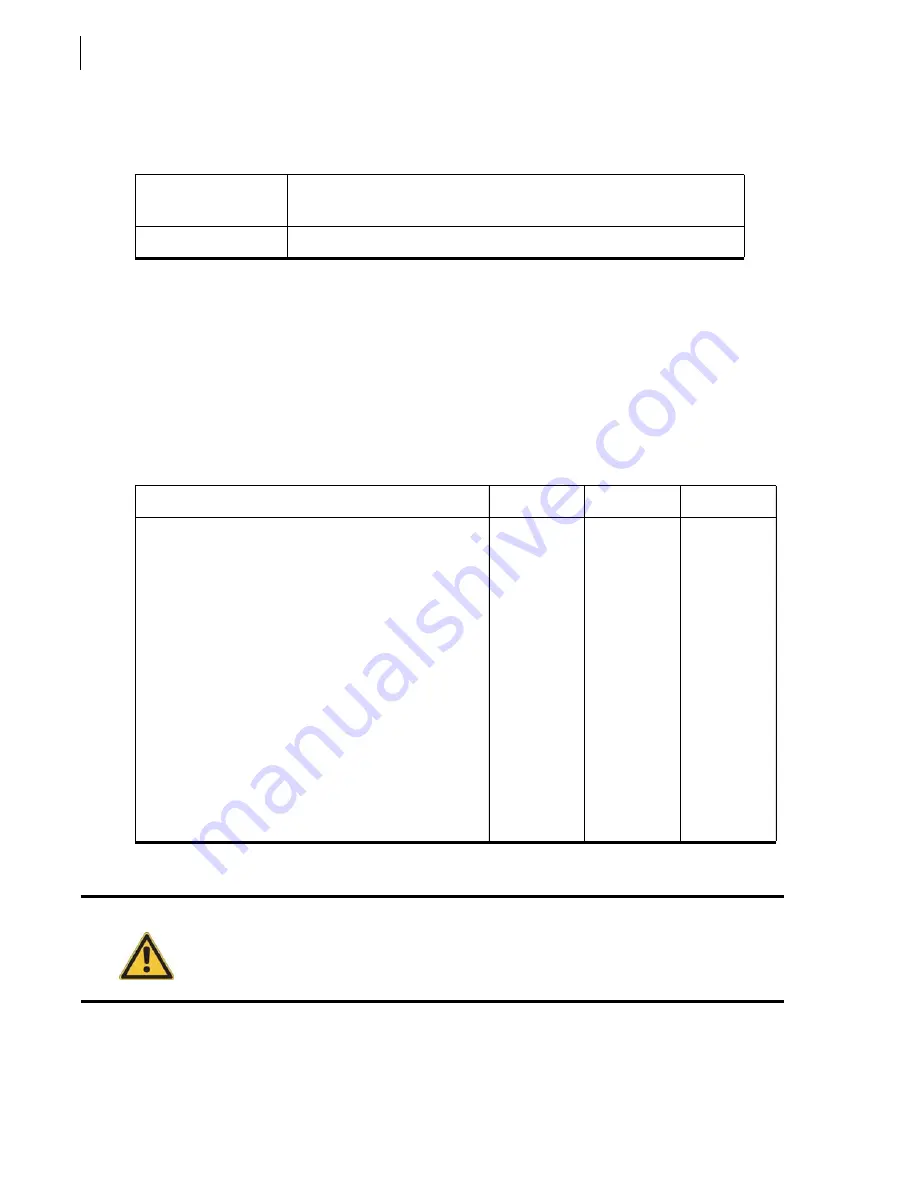

Grade ISO/Viscosity

22

32

46

AGMA NO..........................................................................

Gravity API..........................................................................

Flash (°F).............................................................................

Pour Point............................................................................

Viscosity:

SSU @ 100°F...................................................................

SSU @ 210°F...................................................................

cSt @ 40°F........................................................................

cSt @ 100°........................................................................

Viscosity Index....................................................................

ASTM Oxidation Test (Hours to 2.0 Neut. No)....

ASTM Rust Test, A & B...................................................

Foam Test............................................................................

Vickers Vane Pump Test..................................................

Dielectric Strength (ASTM 877) EC # @ 180°F....

-

33

375

-20

112

40

21

4.1

98

2500

Pass

Pass

Pass

25 Kv

40-37-3 (10)

-

31

380

-20

158

44

30,5

5.2

99

2500

Pass

Pass

Pass

25 Kv

40-37-3 (15)

1

31

390

-20

228

48

44

6.5

99

2500

Pass

Pass

Pass

25 Kv

40-37-3 (15)

Caution!

Do not use engine oil, automatic transmission fluid (ATF) or add diesel

fuel or kerosene to the

hydraulic fluid. Service life of all hydraulic system

components may be adversely affected.

Summary of Contents for 2R-III

Page 1: ...2R III MAINTENANCE MANUAL...

Page 2: ......

Page 3: ...2R III MAINTENANCE MANUAL...

Page 5: ......

Page 6: ......

Page 20: ...10 Introduction...

Page 42: ...32 Safety...

Page 58: ...48 Preventive Maintenance Figure 5 1 Hydraulic tank w return filter 1 2 3 4 5 6 7 8...

Page 66: ...56 Preventive Maintenance...

Page 102: ...92 Troubleshooting...