20

Position the safety bar in the holes of the lower rails of the table

7.4 Lift table maintenance (option)

➢

Frequency:

Every 100 hours or every 6 months.

•

Put the table in the upper stop.

•

Lift the bellow and hold it in place by using the straps (not included).

•

Positioning the safety bar (supplied with the device)

•

Lubricate the lower and upper rails to the right and to the left with graphite grease.

•

Check the oil level in the pump reservoir. It must contain at least 2cm of oil when the table is at the

upper stop, complete with hydraulic oil if necessary.

2cm minimum

Upper rail to be greased

Lower rail

Filler plug

Adjusting the lowering speed:

Loosen to increase the speed

Adjusting the pressure:

Loosen to increase pressure (150bar max)

Lower rail to be greased

Safety bar

Pump tank

Bellow

Straps

Summary of Contents for EASY 2000

Page 1: ...EASY 2000...

Page 2: ......

Page 6: ...6 ATTENTION ATTENTION ATTENTION Area of occasional presence R 15m m Wear protective equipment...

Page 25: ...25 10 MAINTENANCE SERVICE BOOKLET Date Technician Hour meter Operation performed...

Page 26: ...26 Date Technician Hour meter Operation performed...

Page 27: ...27 Date Technician Hour meter Operation performed...

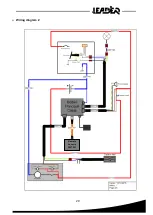

Page 28: ...28 11 ANNEX Wiring diagram 1...

Page 29: ...29 Wiring diagram 2 Remote console 2007267...

Page 31: ...31...

Page 32: ...32 Package leaflet Code EASY2000 0 ZN3 67 EN 0...