DMA860H Fully Digital Stepper Drive Manual V1.0

2

Pulse Voltage

-

5

-

VDC

Isolation resistance

500

MΩ

Operating Environment and other Specifications

Cooling

Natural Cooling or Forced cooling

Operating Environment

Environment

Avoid dust, oil fog and corrosive gases

Ambient Temperature

0

℃ -

50

℃

Humidity

40%RH

-

90%RH

Operating Temperature

70

℃

Max

Vibration

5.9m/s

2

Max

Storage Temperature

-20

℃ -

65

℃

Weight

Approx. 620g (21.9oz)

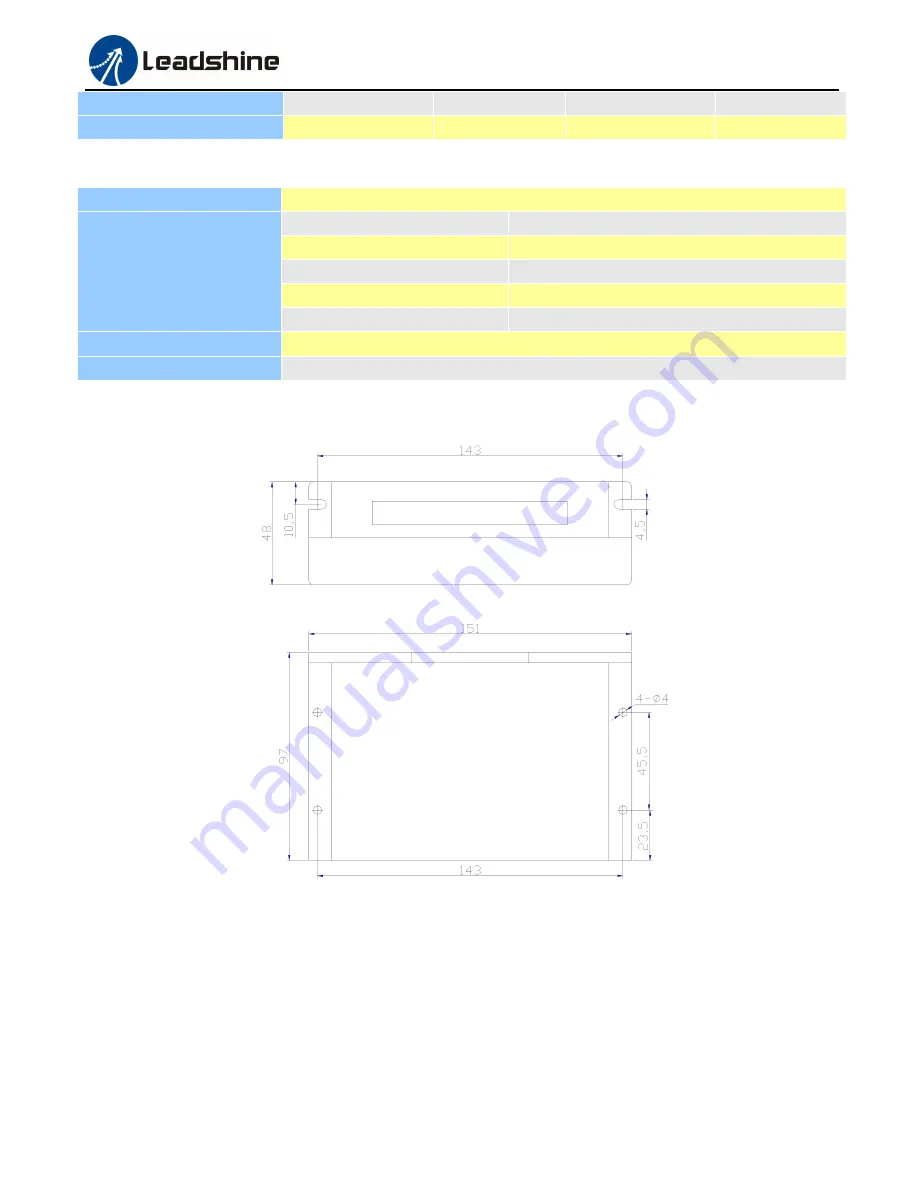

Mechanical Specifications

Figure 1: Mechanical specifications

*Recommend use side mounting for better heat dissipation

Elimination of Heat

Driver’s reliable working temperature should be <70

℃

(158

℉

), and motor working temperature should be

<80

℃

(176

℉

);

It is recommended to use automatic idle-current mode, namely current automatically reduce to 50% when motor

stops, so as to reduce driver heating and motor heating;

It is recommended to mount the driver vertically to maximize heat sink area. Use forced cooling method to cool