M542 Economical Microstepping Driver Manual V1.0

Tel: +086 0755-26434369 11 Web Site:

www.leadshine.com

Remark:

(1)

t

1

: ENA must be ahead of DIR by at least 5

μ

s. Usually, ENA+ and ENA- are NC (not

connected). See

“

Connector P1 Configurations

”

for more information.

(2)

t

2

: DIR must be ahead of PUL effective edge by at least 5

μ

s to ensure correct direction;

(3)

t

3

: Pulse width not less than 1.5

μ

s;

(4)

t

4

: low level width not less than 1.5

μ

s.

11. Protection Functions

To improve reliability, the driver incorporates some built-in protections features.

Over-voltage Protection

When power supply voltage e52VDC, protection will be activated and power indicator LED

will turn red.

Coil-ground Short Circuit Protection

Protection will be activated in case of short circuit between motor coil and ground.

Attention

:

Since there is no protection against power leads (

﹢

,

﹣

) reversal, it is critical to make

sure that power supply leads correctly connected to the driver. Otherwise, the driver will be damaged

instantly. When power supply voltage is lower than +20VDC, the driver will not works properly.

12. Frequently Asked Questions

In the event that your M542 doesn

’

t operate properly, the first step is to identify whether the

problem is electrical or mechanical in nature. The next step is to isolate the system component that

is causing the problem. As part of this process you may have to disconnect the individual

components that make up your system and verify that they operate independently. It is important to

document each step in the troubleshooting process. You may need this documentation to refer back

to at a later date, and these details will greatly assist our Technical Support staff in determining the

problem should you need assistance.

Many of the problems that affect motion control systems can be traced to electrical noise,

controller software errors, or mistake in wiring.

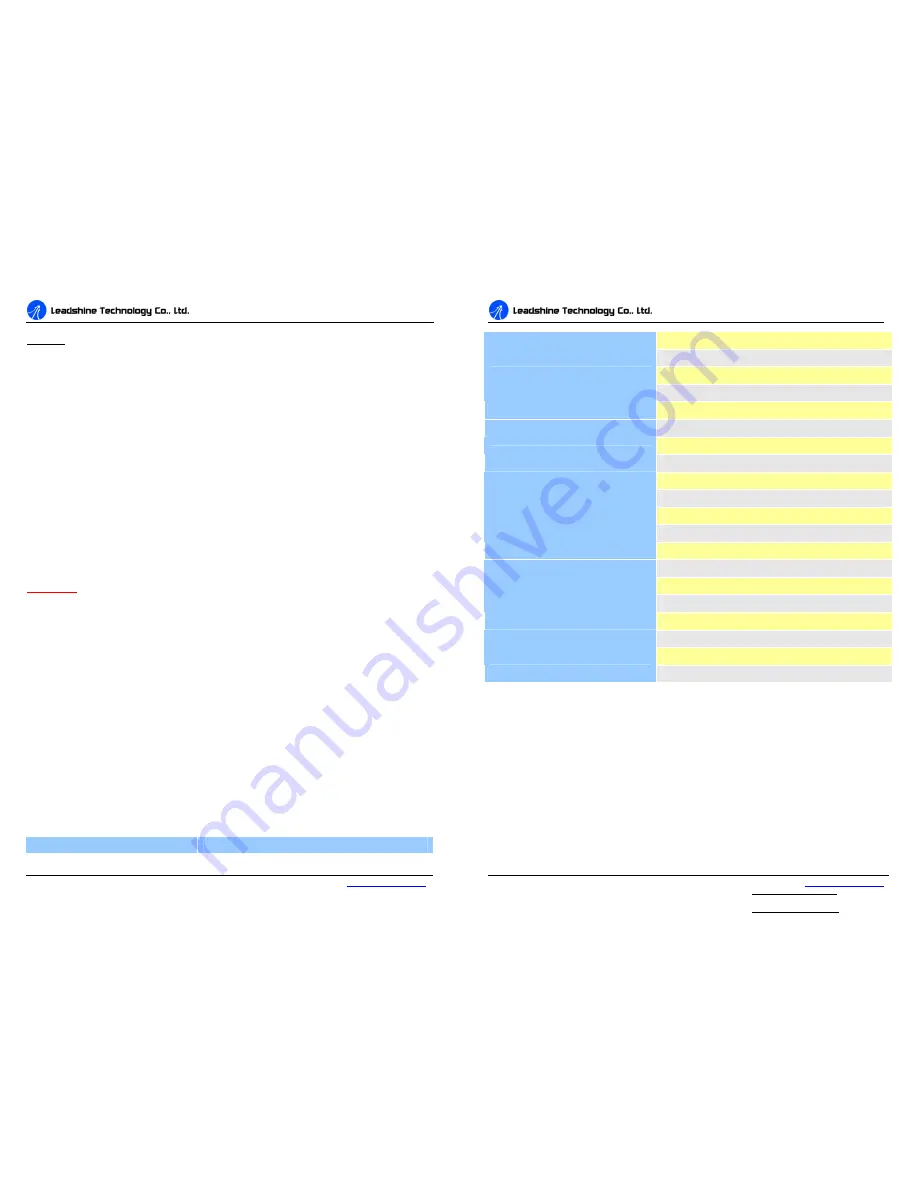

Problem Symptoms and Possible Causes

Symptoms

Possible Problems

M542 Economical Microstepping Driver

Tel: +086 0755-26434369 2 Web Site:

www.leadshine.com

No power

Microstep resolution setting is wrong

DIP switch current setting is wrong

Fault condition exists

Motor is not rotating

The driver is disabled

Motor rotates in the wrong direction

Motor phases may be connected in reverse

DIP switch current setting is wrong

The driver in fault

Something wrong with motor coil

Control signal is too weak

Control signal is interfered

Wrong motor connection

Something wrong with motor coil

Erratic motor motion

Current setting is too small, losing steps

Current setting is too small

Motor is undersized for the application

Acceleration is set too high

Motor stalls during acceleration

Power supply voltage too low

Inadequate heat sinking / cooling

Automatic current reduction function not being utilized

Excessive motor and driver heating

Current is set too high

www.yusto.ru

info@yusto.ru