User Manual for ELD2-CAN Servo

www.leadshine.com

94

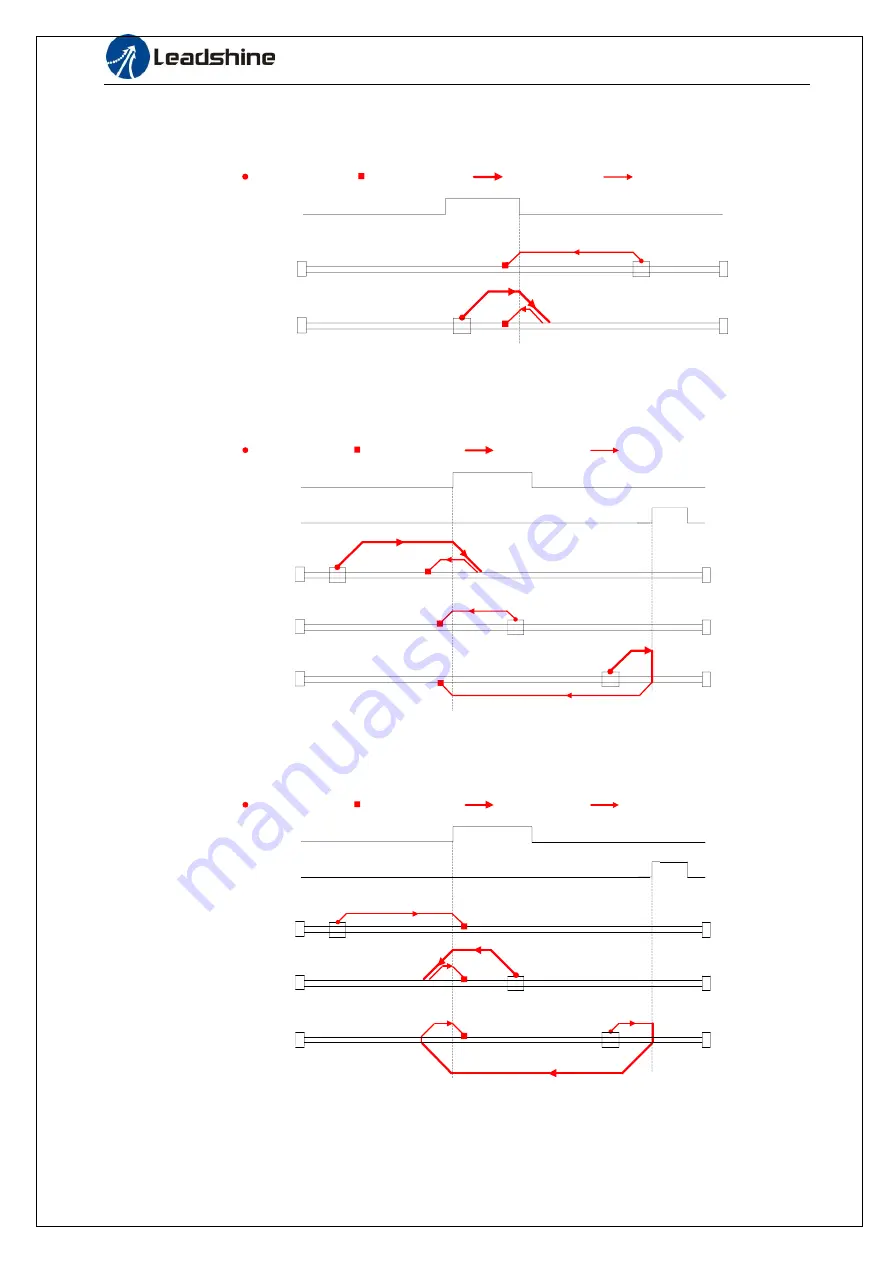

Method 22

:

This method is similar to method

6

HOME-SWITCH

A

B

Start Position

Stop Position

High speed

6099h-01h

Low speed

6099h-02h

Method 23

:

This method is similar to method 7

HOME-SWITCH

B

Start Position

Stop Potion

High speed

6099h-01h

Low speed

6099h-02h

POT signal

A

C

Method 24

:

This method is similar to method 8

HOME-SWITCH

B

Start Position

Stop Position

High speed

6099h-01h

Low speed

6099h-02h

POT signal

A

C