User Manual of iSV2-CAN Servo

www.leadshine.com

28

0:

Incremental position mode

:

The encoder is used as a incremental encoder, and the position retentive at power failure is not

supported.

1:

Absolute position linear mode

:

The encoder is used as an absolute encoder, and the position retentive at power failure is supported..

It is applicable to the scenario where the travel range of device load is fixed and the encoder multi-turn

data dose not overflow.

2: Absolute position rotation mode

:

The encoder is used as an absolute encoder, and the position retentive at power failure is supported..

It is mainly applicable to the scenario where the load travel range is not limited and the number of

motor single-direction revolution is less than 0~(Pr6.63+1)

5: Clean multi-turn alarm

, and open multi-turn absolute function.

It will become 1 when normal clearance, if it’s still 5 after 3seconds, please deal with according to 153

alarm processing.

9: Clear multi-turn position and reset multi-turn alar

m, open multi-turn absolute function.

It will become 1 when normal clearance, if it’s still 9 after 3seconds, please deal with according to 153

alarm processing. Please remember to do mechanical homing.

Notes:

Set to 9 after homing process finished and servo disabled, valid after restart power-supply

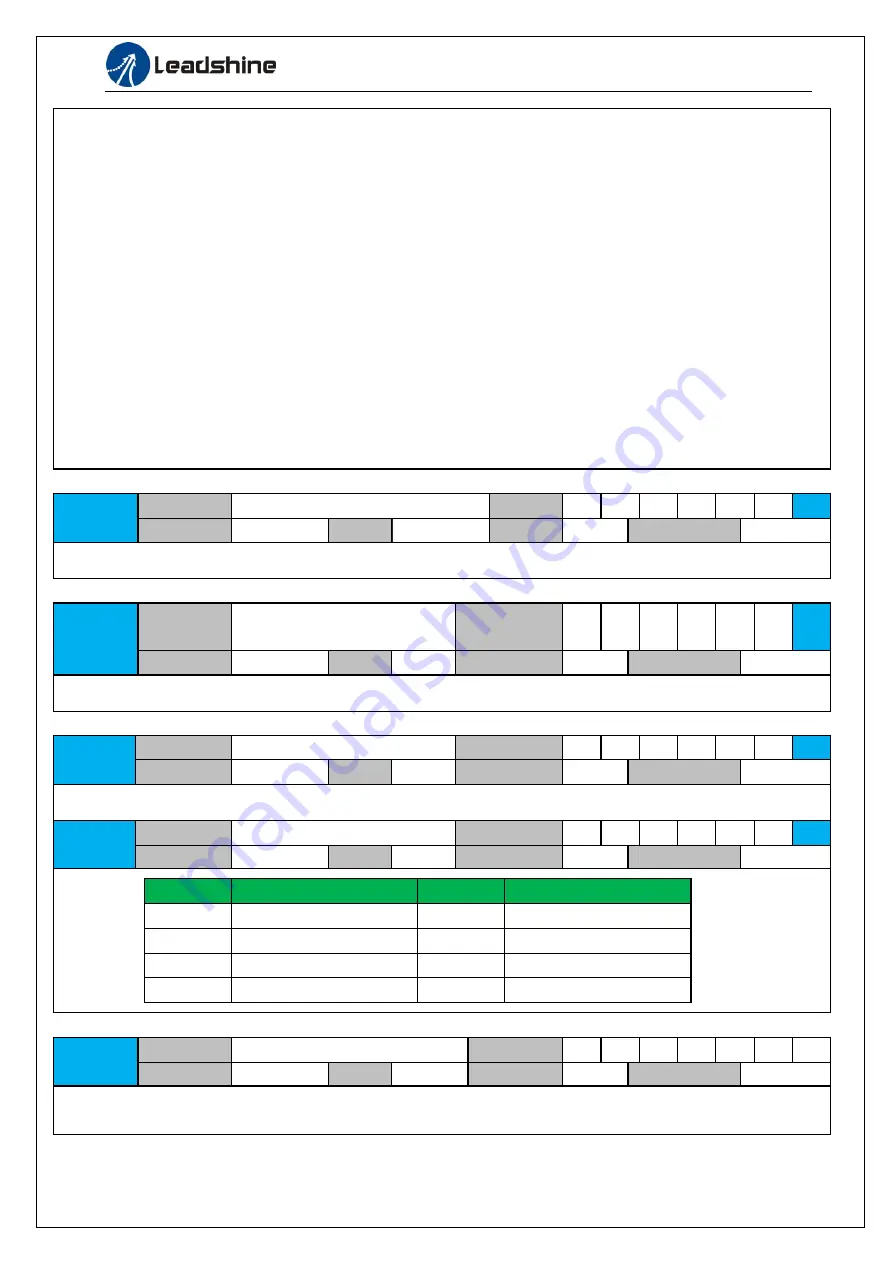

Pr0.16

Name

External regenerative resistance value

Mode

F

Range

40~500

Unit

Ohm

Default

100

Index

2016h

Set Pr.0.16 and Pr.0.17 to confirm the threshold value of the discharge loop to give alarm for over current.

Pr0.17

Name

External regenerative resistance

power value

Mode

F

Range

20~5000

Unit

W

Default

20

Index

2017h

Set Pr.0.16 and Pr.0.17 to confirm the threshold value of the discharge loop to give alarm for over current.

Pr0.23

*

Name

CAN Node ID

Mode

F

Range

0~32767

Unit

—

Default

2

Index

2023h

Setup the Node-ID of the slave station.

Pr0.24

*

Name

CAN Baud rate

Mode

F

Range

0~7

Unit

—

Default

0

Index

2024h

Pr0.24

CAN baud rate (KHz)

Pr0.24

CAN baud rate (KHz)

0

1000

4

125

1

800

5

100

2

500

6

50

3

250

7

20

Pr0.25

Name

Synchronous compensation time 1

Mode

Range

1~100

Unit

0.1us

Default

10

Index

2025h

Synchronous jitter compensation range, used in poor synchronization of the master station.

Note

:

Valid after restart power.