ENGLISH

> Stay alert and watch what you are doing.

> Do not operate the unit when fatigued or under

the influence of drugs or alcohol.

> Read all instructions and safety precautions for

equipmen t and spray material before operating

any equipment.

> Hearing protection is recommended for extended

use.

This tool is double insulated; therefore no

earth wire is required. Always check that the power

supply corresponds to the voltage on the rating plate.

> If the supply cord is damaged, it must be replaced

by the manufacturer or an authorised Service

Centre in order to avoid a hazard.

> When using the tool outdoors, only use extension

cables intended for outdoor use. A suitable rated

extension cable of up to 30 meters can be used

without loss of power.

> Electric safety can be further improved by using a

high sensitivity.

Use only a 3-blade grounding plug and a 3-slot

receptacle that will accept the plug on the product.

Make sure your extension cord is in good condition.

When using an extension cord, be sure to use one

heavy enough to carry the current your product will

draw. An undersized cord will cause a drop in line

voltage resulting in loss of power and overheating.

If an extension cord is to be used after the cord type

designation. For example, a designation of SJTW-A

would indicate that the cord would be appropriate

for outdoor use. For proper size cords see chart.

GUIDE FOR EXTENSION CORD USAGE:

Type of cable

Up to 5 metres

From

5 to metres

10 metres

Parallel

2x 1.0mm

2

2x 1.5mm

2

WARNING! Some spray materials contain

chemicals known to cause cancer, birth defects or

other reproductive harm. To reduce your exposure

wear appropriate safety equipment such as face

masks, gloves, and other appropriate protective

equipment. Please review and follow the safety

precautions on the paint container.

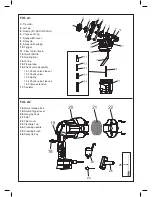

FEATURES (FIG. A, FIG. A1, FIG. A2)

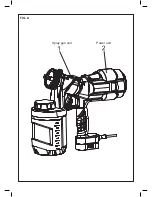

1. Spray gun unit

2. Power unit

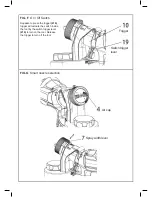

3. Tip collar

4. Air cap

5. Nozzle (Φ1.5mm/Φ3.5mm)

6. Y-type seal ring

7. Spray width lever

8. Spray tip

9. Spray unit housing

10. Trigger

11. Flow control knob

12. Quick refill lid

13. Sealing liner

14. O-ring

15. Pickup tube

16. Check valve assembly

16.1 Check valve sleeve 1

16.2 Check valve

16.3 Spring

16.4 Check valve sleeve 2

16.5 Valve extension

17. Canister

18. Quick release lock

19. Switch trigger lever

20. Hanging hook

21. Filter

22. Filter cover

23. Viscosity cup

24. Cleaning needle

25. Cleaning brush

26. Spray tip key

ELECTRICAL SAFETY

EXTENSION CORD