ENGLISH

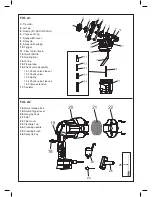

FLOW CONTROL KNOB (FIG. A1)

The flow control knob (#11) regulates the amount

of liquid that can be sprayed. Turning the flow knob

clockwise increases the flow of liquid. Turning the

knob counter anti-clockwise decreases the flow of

liquid.

Tip: Always test the spray pattern on scrap

cardboard or similar material first. Begin with flow

control knob on the highest flow setting. If less flow is

desired, dial the flow control knob anti- clockwise to

decrease the flow of liquid. Heavier, thicker materials

should be sprayed with the flow control knob on high

flow setting. Thinner materials should be sprayed

with the flow control knob on low flow setting.

> Practice spraying on a piece of scrap material

such as cardboard to test your spray pattern and

become familiar with the flow control feature of the

sprayer.

> Ensure surface to be sprayed is free of dust, dirt,

and grease.

> Ensure spray area is clean and free of dust that

could be blown onto newly sprayed surfaces.

> Cover any areas not intended to be sprayed.

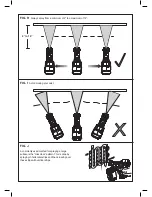

> Always spray from a minimum of 2 in to a maximum

of 12 in (FIG. H).

> A commonly used method for spraying a large

surface is the “crisscross” pattern. This is done by

spraying in horizontal strips and then crossing over

these strips with vertical strips (FIG. J).

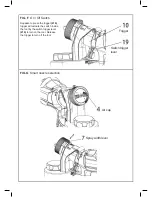

> To get an even spray distribution, always keep your

arm at the same distance (FIG. H) from the surface

you are spraying and avoid moving your wrist

(FIG. I).

> Maintain smooth and consistent speed which will

help avoid inconsistencies. Begin spraying after

the pass has begun and release trigger before

stopping the pass.

> Avoid spraying too heavily in any one area. Several

lighter coats are better than one heavy coat which

can lead to running and dripping. Remember that

the flow control knob regulates the amount of

liquid that can be sprayed. Turning the flow knob

clockwise increases the flow of liquid. Turning the

knob counterclockwise decreases the flow of liquid.

If runs or drips do occur, have a dry paint brush on

hand to smooth them out.

> Turn the power unit off and unlpug the cord when

not spraying for any length of time.

WARNING! Be sure to use appropriate

protective gear.

> Do not use materials with a flashpoint higher than

60°C (140°F) . Flashpoint is the temperature that

a fluid can produce enough vapors to ignite (see

coating supplier).

> Make sure clean up area is well ventilated and free

of flammable vapors.

> Always spray outdoors when spraying cleaning

solution through sprayer.

> Do not submerse power unit.

> Use drop cloths during pouring, mixing, and

viscosity testing of materials to be sprayed to

protect your floors and anything else in the

spraying area that you wish to remain untouched.

TO BEGIN CLEANING:

> Turn the power unit off, unplug the cord and

disconnect air hose from sprayer.

> Unscrew the canister from the sprayer and

pour any remaining liquid back into the original

container (FIG. K).

> Pour a small amount of the appropriate cleaning

solution into the canister (FIG. M). - Warm soapy

water for water based materials - Manufacturers

recommended cleaning solution for oil based

materials.

> Screw on the canister back to the sprayer securely

and vigorously shake the sprayer.

> Unscrew the canister and properly dispose of

cleaning solution.

> Refill the canister with a small amount of new

cleaning solution. Screw on the canister back the

sprayer. Reattach the spray gun unit to the power

unit, plug in the cord and turn on the power unit.

> Spray the cleaning solution through the sprayer

onto scrap material for 2 to 3 seconds (FIG. N).

> Turn the power unit off, and unplug the cord.

> Unscrew the canister from the sprayer.

DEVELOPING THE PROPER

SPRAYING TECHNIQUE

CLEANING