ENGLISH

TROUBLESHOOTING

TROUBLE! ATOMIZATION IS TOO COARSE

WHAT’S WRONG?

WHAT TO DO…

Viscosity of material too high.

Thin material per manufacturer recommendation.

Flow control knob setting too high.

Decrease flow control setting.

Material accumulated /clog inside nozzle.

Clean

Air inlet blocked.

Clean or change air filter.

Canister loose

Screw canister tightly in place.

Quick refill lid loose

Screw quick refill lid tight in place.

TROUBLE! SPRAYER PULSATES.

WHAT’S WRONG?

WHAT TO DO…

Air filter clogged.

Clean or change air filter.

Material in canister almost empty..

Refill canister.

Canister loose.

Screw canister tightly in place.

Quick refill lid loose.

Screw quick refill lid tight in place.

TROUBLE! SPRAY MATERIAL DOES NOT COVER PROPERLY

WHAT’S WRONG?

WHAT TO DO…

Flow control knob setting too low.

Increase flow control setting.

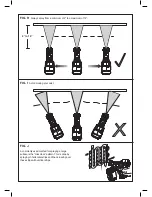

Clearance to target area too large.

Reduce spray distance.

Too few spray paths sprayed over target area.

Apply more spray paths sprayed over target area.

Viscosity of material too high.

Thin material per manufacturer recommendation.