(MWQERXPMRKSJTVMRXMRKFPSGOTEVXW

%P]WQEMRXIRERGIQERYEP

%%

(MWQERXPMRKSJTVMRXMRKFPSGOTEVXW

6IQSZEPSJLIEHTVSXIGXMSRGSZIV

To remove the cover protecting the heads, do the following:

- facing the head, grasp the sides of the cover, move them apart slightly and

pull the cover upwards.

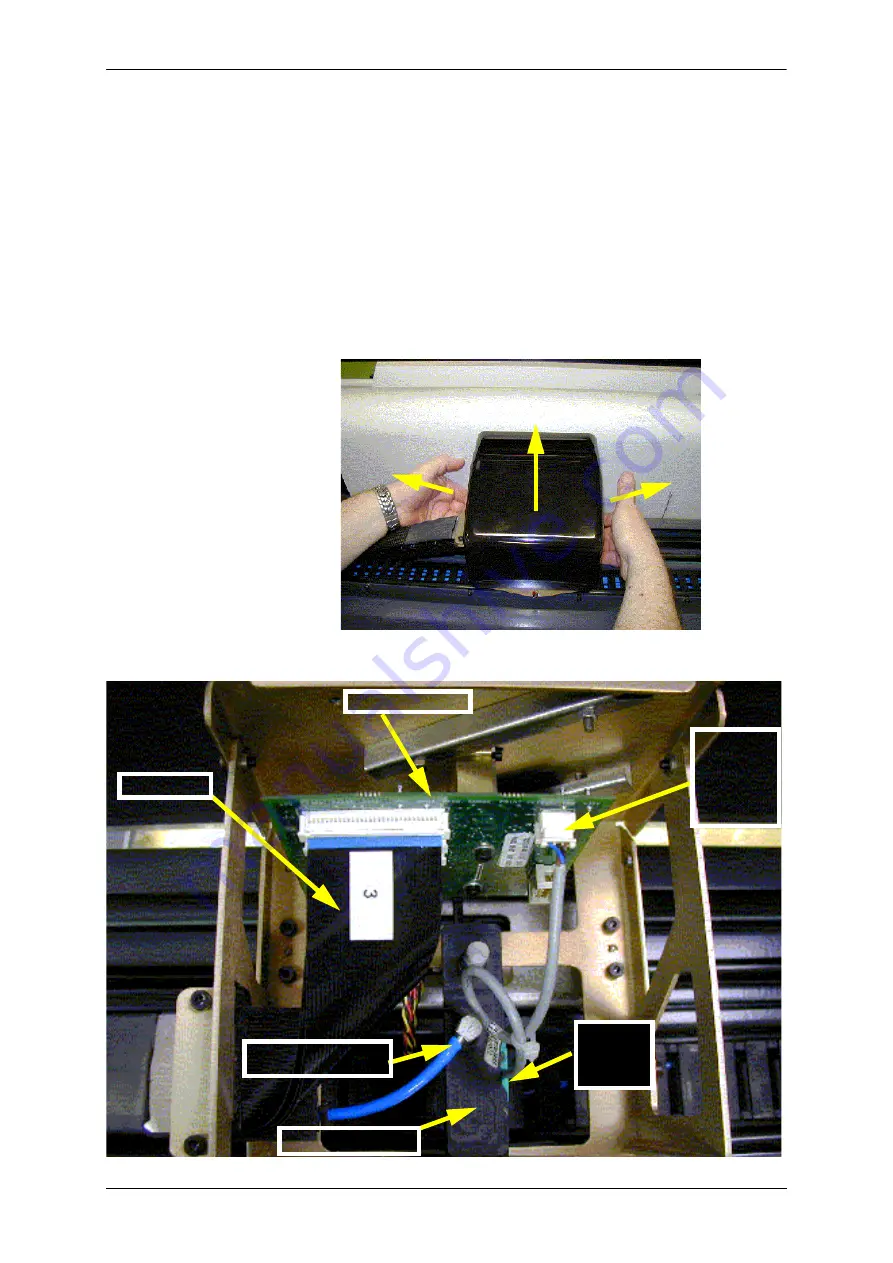

6MFFSR

-ROPIZIP

WIRWSV

)PIGXVSRMGWFSEVH

&YJJIVVIWIVZSMV

'SRRIGXMSR

GEFPIJSVXLI

VIWIVZSMV

PIZIPWIRWSV

-ROMRPIX