20

2.0 Cabinet Installation,

continued

745-573-B0-001 REV. A

NOTE:

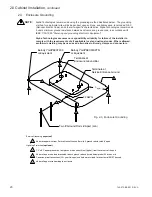

Alpha Technologies recommends using the grounding method illustrated below. The grounding

method for a particular site will be dependant upon soil type, available space, local codes, NEC

(National Electric Code), and other site-specific characteristics. Alpha Technologies recommends

5 ohms minimum ground resistance between enclosure and ground rods, in accordance with

IEEE 1100-1999

“Powering and grounding Electronic Equipment”

.

Alpha Technologies assumes no responsibility or liability for failure of the installer to

comply with the requirements of all applicable local and national codes. Where allowed,

exothermic welding may be used as an alternative to Burndy clamps and connectors.

1

Service Grounding

(required)

#6 bare copper wire from Service Neutral/Ground Bar with 2 ground rods located 6' apart.

Lightning Protection

(optional)

1/2" x 8' Copper ground rod, four places driven about 2 feet (typical) from the corners of the pad.

#6 bare Copper wire loop terminated to each ground rod and buried below grade (30 inches, min.

Corrosion-proof connections (25+ year life-span) and hardware suitable for direct burial MUST be used.

#6 bare Copper wire from loop to enclosure.

2

3

4

Burndy YGHP58C2W-2TN

or Equivalent

Burndy YGHP58C2W-3

or Equivalent

Terminate at

Enclosure Ground Bar

Terminate at

Service Entrance Ground

Two 8' Ground Rods 6' Apart (min)

4

1

2

2' min.

#2 AWG

2

2

2

3

Fig. 2-3, Enclosure Grounding

2.3

Enclosure Grounding