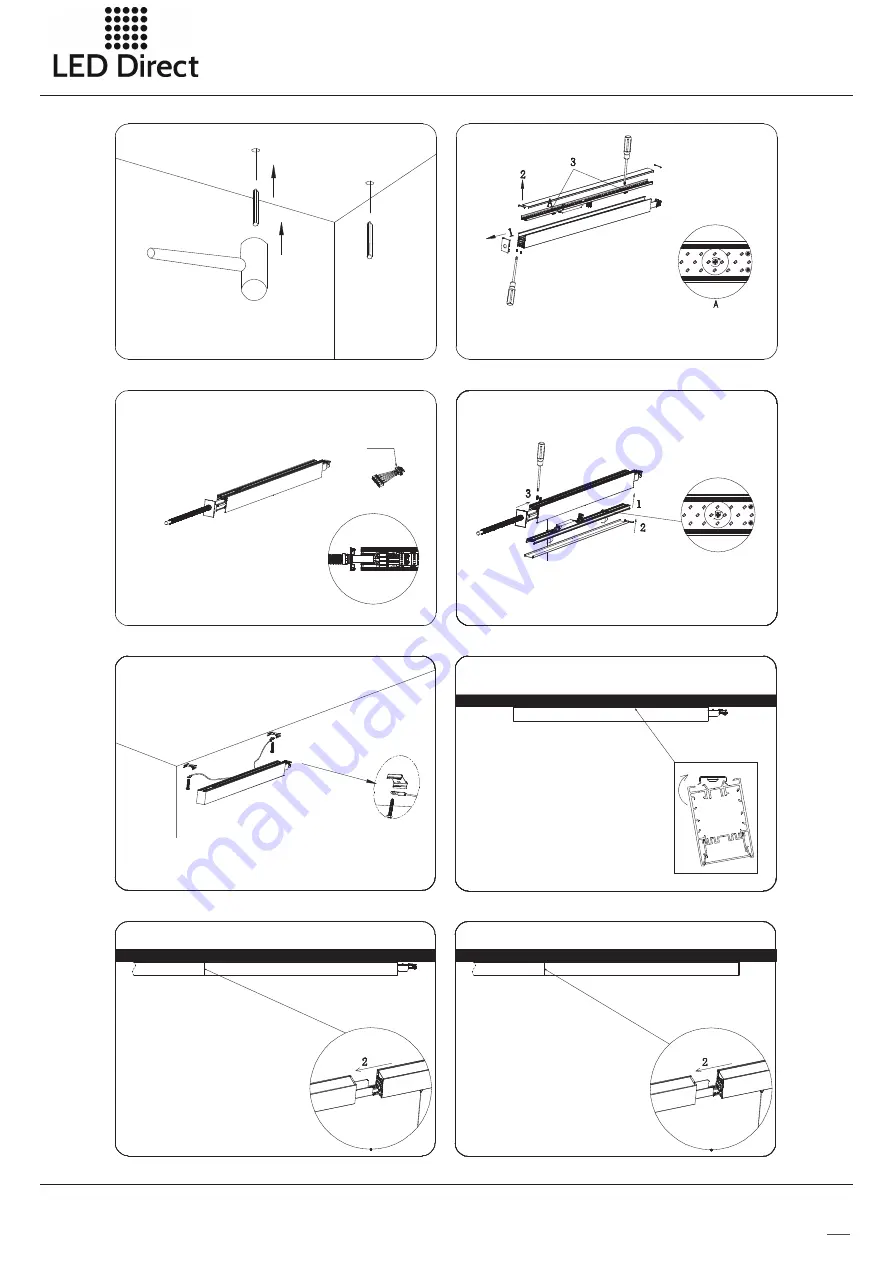

Install lampbody of the end run

1.Snap the clamp of suspendent rope into

slot of lamp profile;

2.Insert female connector of end run into

male connector of previous run.

Install lamp body of the middle run

1.Install ceiling lamp into profile slot of the

middle run lamp;

2.Insert female connector of the first middle run

into the male connector of the first run ; and

insert female connector of the next middle run

into male connector of previous middle run.

3. Splicing quantity

When input voltage is 110V, N*P

<

800W

When input voltage is 277V, N*P

<

2270W

N is total run, and P is power of single lamp

P8

Install the first run lamp body

1. Install the cooling panel into shell of lamp body, and rotate screws of

fixing card clockwise by 90° to fasten the cooling panel into the lamp;

2. Press and mount the PC cover and inside cover plate on lamp;

3. Clip the end cap on the lamp,and fasten screws on the top of end cap.

1. Break through knockout hole on splicing profile;

2. Fix the

conduit in the knockout hole;

3. Insert the female connector into male

connector of lamp;

4. Thread AC connecting wire through

conduit,

and respectively connect N,GND,L, DIM+,DIM- of

connector.nsion, and hammer the rubber plug into hole

connector

Connect the input cable

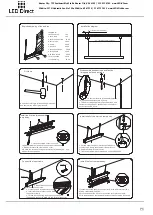

Install the clamp of the first run lamp body

Thread the screw through fixing holes of safety rope and clamp, and

fasten the screw with rubber plug in the ceiling

Install the first run lamp body

According to the figure, install the clamp on one

side, then rotate and press mounting to another

side of the clamp;

Drill hole

Drill hole according to corresponding dimension,

and hammer the rubber plug into hole

Installation of the first run-disassemble lamp body

1. Unscrew the screws on the side of

end cap with screwdriver;pull the end

cap out by hand;

2. Dismantle inner side cover and PC cover;

3. Rotate two screws of fixing card counter-clockwise by 90°, and

dismantle cooling panel.

Kansas City: 735 Southwest Blvd Ste B • Kansas City, KS 66103 | 913.912.3760

www.LED-KC.com

Wichita: 327 N Hydraulic Ave, Ste 100 • Wichita, KS 67214 | 316.712.7614

www.LED-Wichita.com